Find Industrial garbage can molds supplier

The features for Sino Mould in Industrial garbage can molds:

5. Best cooling system for reduce cycle time, around 60-70sec for 120L garbage can.

Sino Mould will show its new solution for double color injection molding by showing a PC double color cup mould and L double color injection molding machine. This is a new solution for double color injection molding double color plastic mould. This shall be one of most significant mould among all Plastic mould Chinaplas 2014

This PC double color cup mould has different structure from the common double color mould. For the traditional double color mould, it is two moulds fixed by one plate and the machine plate will rotate. But this new double color mould will rerate by itself.

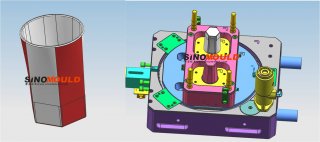

Also the injection gate place is different from the common one. The main nozzle for injection is located in the front, similar to the common mould. And the second is in the side. (see the photo below to know)

This PC double color cup mould is specially designed for our new L angel double color injection machine. This new double color injection molding technology will become more and more popular because of its flexibility and economic cost.

Want to know more about our PC double color cup mould and the new double color injection molding technology, pls contact Sino.

Cina

export@sinomould.com

PC double color cup mould

Blowing bottle production line includes:

Auxiliary machine

Email:export@sinomould.com

Skype:anole-hc-01

How to buy a good mould is always a big topic. According to my experience in IML mould area, I would like to share with you some important IML moulds inspection points. When you buy an IML moulds, you should pay attention to both of the product quality and mould quality.

IML moulds inspection key points mainly include two parts:

1.Mould inspection

--mould design quality control. In order to reach high quantity and high speed production requirement. IML mould have strict requirement to the cooling system, mould strength. Pay attention to them before the mould tooling.

--Steel hardness. Steel quality and steel hardness are relate to the mould life, mould precision, mould polish performance. So it will be better to let mold makers supply you steel certificate. Check if there is welding mark when you receive the moulds.

--Mould operating. Good mould should be ran automaticly, continuely without any problem. Also the cycle time is very import to be checked.

2. Product inspection

--Check the injection balance of each cavity by just injection half product. This method is very helpful to round IML containers.

--Check if there is any flash, burr, bubble, deformation on the product.

--Do water testing if you need it seal water.

--Check the security hook.

Any question about IML moulds, you can feel free to contact Ms.Summer via

export@sinomould.com .

Our company with rich plastic injection caps mold experience is becoming more and more popular in “China plastic mold town”Taizhou, huangyan. Our company makes many different kinds of the cap molds, such as water cap, flip top cap, spray closure cap, shampoo closure cap, push puller, medical bottle caps, medical bottle caps, anti-theft type cap , 5 gallon plastic cap, buckle a insert lift cover, special cover cap lipstick, etc, we are China caps mold maker.

Usually we canl use plastic material for caps, such as: PP, PC, PS, HDPE, LDPE, PMMA, etc. As we know, different plastic cap material suited for different area, once you place the order to us, kindly show us the function of the caps. Besides, we usually use S136, 2316, H13 for making the mold steel, and use hot runner pin point gate or submarine gate for the molds, from 4 cavities to 48 cavities, if you have enough big machines.

Before shipping the molds, we will kindly check the following points of the caps:

1.check the color 2. The gate is smooth or not 3. The surface us polish or texture 4. Logo and the cavity NO. is ok or not 5. With fur or not of the surface 6. Matched with the bottle or not 7. Check the thread pitch match with bottles crew or not 8. check the depth of the thread and thread depth of bottle neck

We areChina caps mold maker, if you are interested in our caps molds, contact me.

Email:export@sinomould.com

Skype:anole-hc-01

With the development of the technology and economy, more and more customer prefer the product which is with the beautiful appearance to the traditional product. IML seems to be the popular way all around the world. We Sino mould could offer you the whole IML production line.

In order to make a IML production line, we need to choose the suitable mould, injection machine, Equipment and so on, pls pay attention to the below list:

IML production line will be the hottest trade in the near future, do not hesitate to come to us, we will offer you a perfect production line.

Sino Package Mould Co., Ltd, a subsidiary of Sino Holdings Group, is professional PET preform mouldmaker in China .We have 20 years experience in offering special PET preform mould to our customers. What’s more, we can offer customers all over the world high quality PET preform mould with diamond service.

5. Good after-service: when the customer buys the mould from our company, if the customer need, we could send our professional engineers to customer’s factory to test the mould and offer trainings to theirs engineers.

Nowadays with rising price of everything, Customers prefer to make preform mould with interchangeable parts for this can save many investment, and it can also using the same mold to manufacture different types of the preform molds models. We offer nterchange PET molding solution and molds maker in China.

The point suit for making the interchange PET moldings as follows:

Interchange weight error range within 5g, If we make two versions of neck for the same mould, then the products come out only differs in the neck part, the PET molding body is same, but the neck height is the same, otherwise, it will be a parting line of the surface of the neck.

Interchange mold parts:

1. Core parts interchange

2. Half mold interchange of the molds: core, cavity sprue, screw, cavity fix plate, stripper and slide

Besides, we use s136 and 2316 mold steel for preform molds, HRC is 50+/-2, we can also offer you the related the PET preform injection molding machines the auxiliary machines. We offer you not a mold, but a fine solution. You can also visit our website:http://www.sino-pk.com/

We offer nterchange PET molding solution.

Email:export@sinomould.com

Skype:anole-hc-01

Sino Mould is a leading Plastic Basket Mould maker in China, can offering high quality and fast cycle Plastic Laundry Basket Mould, shopping basket moulds, etc.

As a professional plastic basket mould maker, we are experienced with various kind of plastic Laundry Basket Mould with cooper beryllium. Below is some basic information for plastic Laundry basket mould specs we made recently for a Brazil customer:

Laundry basket size: 38cm diameter*39cm height

Basket mould cavity: 1 cavity

Plastic basket mould size: 800*780*616mm

Suitable injection machine: DKM500T injection machine

Core/cavity material: 718H

Chair Mould features: simple structure mould, optimal cooling system, good polishing, precision air venting

Delivery time: 60days

Above mould has 4 slides in the cavity for better product appearance. If you want to reduce cost, we can change product design to cancel the slide. The mould size will relatively smaller and mould cost will be lower.

Looking for high quality Plastic Laundry Basket Mould? Pls contact us.

Contact: Cina

export@sinomould.com

As a professional cap mould company, we are good at various multi-cavity cap moulds manufacturing, for instance, flip top cap mould, spray cap mould, shampoo cap mould, water cap mould, 5 gallon cap mould, oil cap mould, and Disc cap, etc. we offer every customer international market complete and high precision cap molding service.

Email:export@sinomould.com

Skype:anole-hc-01

With the rapid development of China's automobile industry, automotive products are more and more widely use of plastic products. We Sino Mould is a professional automotive parts molding maker, who is specialized in designing, developing, manufacturing all kinds of plastic automotive parts moulds.

We have nearly 60 design team for mould analysis and mould design. The main software we usually use is: Unigraphics, Pro-E, Solid works, Mudflow. What’s more, High precision tooling machine with our working teams such as project dept., quality dept. We are using international advanced CAD/CAM/CAE methods and integrated manufacturing systems to service the worldwide. To keep competitive edge, we spare no effort to update our equipment, especially for mold making. Our in-house facilities include CNC machining centers, wire & ram EDM machines, die-spotting presses, CMM, just to name a few.

In addition to the application of latest machining and mold making techniques, we are confident that we can take up any challenge in the highly competitive market.