Plastic car wheel cover molds manufacturer

Plastic car wheel cover molds manufacturer Sino Mould, we can offer high quality plastic car wheel cover molds plastic auto wheel molds, wheel cover molds, auto wheel cover molds manufacturing and export, we have made various kinds brand car wheel parts, the brand of car wheel like RENAULT,KIA, PEUGEOT and so on.

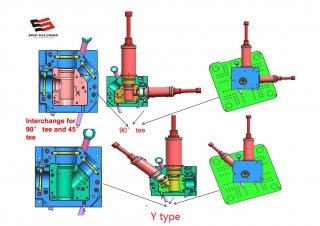

Sino Mould is a leading plastic pipe fitting mould maker in China, offering with PVC fitting mould, pipe fitting moulds. As a leading plastic fitting mold maker, we can offer multi-cavity solution, curving slide solution, collapsible core pulling solution,Interchangeable Fitting Mould.

For example, we make an Interchangeable Fitting Mould for PVC reducing Tee 160mm and Y type 160mm. Below is some basic information:

Product:

1.160mm Tee, 934g

2.160mm Y-type, 1098g

Material: PVC

Design: with collapsible core puling

Core and cavity system: 1.2316

Mould size: 1301X2035X708mm,

Weight: 1552 KG

Suggest injection machine size 500T or 650T injection machine

Hydraulic cylinder: Merkle

Water nipple brand: Staublil

If your productivity is not very high, it will be a big cost to make two moulds for two products. Then Interchangeable Fitting Mould will be your best choice, which allow buying mould at low cost. But you still can produce two kind of product.

Interested in Interchangeable Fitting Mould? Pls feel free to contact Sino.

contact: Cina export@sinomould.com

Email:export@sinomould.com

Skype:anole-hc-01

Our company is a preform mold maker in China for 15 years, with advance injection molding machines and high quality plastic preform molds, we are developing fast and fast in the past, now our company own more than 100 senior designers and the professional engineers and a powerful QC department, you can visit our website: http://www.sino-pk.com/,

Our company make 10ml to 10L preform molds, we have the ability to make the customized preform molds, just tell us your requirement and we will 0ffer you a satisfied solution for you. On the other hand, consider that save some customers investment, our company also can make some interchange molds of the preform moulds, then customers can have more choice to making different size of the preforms in the same molds.

we can also offer our customers plastic injection preform molding machine, plastic raw material dryer, plastic raw material auto loader ,plastic injection mould , air compressor, water chiller.

Besides, we also make the matched cap molds, we offer you not just a prefrom mold, but a turnkey solution. We will offer you the whole line of the preform molds projects.

if you are interested in our molds, please kindly contact me, we are preform mold maker in China.

Email:export@sinomould.com

Skype:anole-hc-01

Are you still worry for finding the plastic injection molding molds supplier?

Are you confusing which is the better maker of the plastic injection moulds?

Please come to Sino, we offer you not just a mold, but a fine solution.

Sino specialized in different kinds of the plastic injection molding machines for two decade years, such as: home appliance mold for plastic chair mold, table molds, different kinds of the containers molds, buckets molds, kitchen molds for spoon&fork&knife molds, bowl molds, thinwall molds, pipe fitting molds, packaging molds, auto molds and so on. We offer one stop service of the injection molds.

We also offer the plastic injection molding machines, such as: high speed plastic injection molding machines, servo power plastic injection molding machines, double color plastic injection molding machines, PET&PVC plastic injection molding machines, variable plastic injection molding machine, etc. besides, we will also offer the matched auxiliary machines, like, auto loader, chiller, cooling tower, mixer, crusher, temperature controller, dryer. You can visit our company website: http://www.sinomould.com and http://www.dakumar.com.

We will offer you the best design for all the plastic injection molds, for the cooling system, ejection system, ejector system and so on. Now we are more and more popular in China.Weoffer one stop service of the injection molds.

if you are also interested in our products, please kindly contact me.

Email:export@sinomould.com

Skype:anole-hc-01

We are biggest toilet seat cover mould maker, we offer SMC toilet cover mould, SMC toilet seat mould, BMC toilet cover mould,BMC tolilet seat mould,we can design toilet cover mould with humanized and high efficiency moulds.

What is the advantage of gas assistant pallet mold ? how to make gas injection molding pallet mold? What equipments you need to start this new plastic molding plant? Good questions.

With latest development of injection molding technology, SINO MOULD is applying gas assist technology into pallet injection molding process. This mean traditional plastic pallet will be replaced with new pallet internal hollow channels, at the same time, the pallet gets more rigid, less weight and improved benefit during racks.

Sino is experienced in excellent design combined with the gas assist production technology, the pallet has longer life and less cost and therefore, the development of gas assistant pallet mold will come to the latest mold market.

Sino offer turnkey solution for the gas assistant pallet mold manufacture. The line include the special designed gas assistant pallet mold, injection molding machine with less injection volume and smaller model, gas production system and auxiliary equipment for material loading, color dozer, material recycling system and so on. Also we offer training and technical support of the plant building.

Thanks for your attention for SINO gas assistant pallet mold and gas molding system for plastic pallet molding line, and welcome your enquiry for pallet molding.

Send your enquiry to export@sinomould.com

SKYPE:sinomould.dakumar2

How can we order chair injection mould? When a customer begins their chair project, they select the mould company very carefully, because seldom of the mould companies can make a good chair mould. We Sino mould who has more than 15 years experience in making plastic mould will be your best choose.

Our advantages are as below:

Our company is specialized in making plastic injection bucket molds for many years, such as: 500ML, 700ML ,370ML, 620L, 1L, 1.3L, 2.2L, 5L, 10L, 15L, 18L, 20L, 25L, etc. Annual we export about 200 sets of the plastic injection buckets molds to all over the worlds, these plastic buckets molds obtain the customers ‘ high praise of the good quality and the mold design. We are plastic injection bucket mold maker in China.

We can use 2738 or 718 mold steel, HRC 35-38, we can also use 2311 or P20, HRC 29-30, we can also use 2738, S136, the mold steel depend on the your requirement of the mold life and the product quality. In order to have a good cooling effect, we can add the copper of the top of the core and the bottom of the cavity, which will reduce the cycle time. Besides, cooling line will around the buckets wall of the plastic inejciton molds. We use hot runner point gate for small plastic injection pail molds , hot runner direct gate for bigger buckets molds, using variable hot runner direct gate for the biggest plastic injection buckets molds. We company can also offer you the related plastic injection molding machines and the related auxiliary machines.

If you are interested in our plastic injection buckets molds, please contact me. we are plastic injection bucket mold maker.

Lucy

Skype: anole-hc-01

E-mail: export@sinomould.com

Sino is an experienced mould maker in china, especially for the perform moulds, here I want to introduce how to avoid perform mould bubble.

The reasons for the bubble, since there is air in the injection machine or when injection appears in mould operation. And the bubble normally appears in the side wall. So here are three ways that may cause the bubble and the ideas of how to avoid perform mould bubble First, In the process of raw material plasticizing due to the improper compression there will be air in the melting material. To avoid the bubble, we can do three actions,

1.increase the screw pressure.

2. Adjust the screw backward position to ensure the Buffer point.

3. Check whether there are plastics bridging phenomenon in the outlet of the extruder machine.

Second, the air will be into the plastic with improper reducing the pressure. Facing this phoneme we can shorten the screw back up distance or shorten the back up time to increase the pressure. Third, the injection unit have over high temperature will cause the the feeding section temperature is too high will cause the molten material premature air. So to avoid that we should take good control of the temperature

The above are the information for avoid perform mould bubble if u are any interested, please contact me freely.

Posted by: Helen

Skype: sino.group10

E-mail:export@sinomould.com

Among all kinds of the plastic mould we made before, the plastic bucket mould is one of the most products that we made. we are a big plastic bucket mould manufacturer in china and good at designing and make such plastic mould , such as paint bucket, water bucket, rice bucket and so on.

When begin the mould, the most important step is to choose a good mould material. Usually we use 2311, P20, if you need higher standard mould, we recommend 2738 with the hardness35-38. Also we will make a good cooling system behind the moulding surface; if you use the copper beryllium will be better, because it could speed up the cooling speed and reduce the cycle time. About the gate, the little bucket, we usually use point gate, if it is a big bucket, we will use big gate or multiple big gate. After making the mould, we need to check the wall thickness of the bucket, the weight, the flash, the strength and so on. We have a strict quality control center to guarantee the mould quality.

Recently, plastic products with wicker or rattan gradually find its popularity among the consumers. Sino Mould has offered many plastic injection moulds for Plastic wicker item moulds during last year, such as Plastic wicker drawer mould, Plastic rattan basket mold, Plastic rattan furniture molds, wicker drawer moulds.

For Plastic wicker drawer mould, we have made 1 cavity and 2 cavity moulds for Italian Mazzei Company. The moulds are with slides for the special wicker texture.

Below are some details for 2 cavity Plastic wicker drawer mould:

Product name: plastic wicker drawer

Product dimension: 370*250*170mm

Product thickness: 1.5mm

Mould size: 950*740*780mm

Hot runner system: 2 tip valve gate hot runner system measure up to DME

Mould steel: 1.2738 for good polishing effect, long mould life for short cycle injection molding

This drawer is picked by robot so the drawer moulds run semi-automatically and cannot drop by itself.

If you want to more information for plastic wicker drawer moulds or mould for other item with wicker or rattan texture, such as wicker table moulds, rattan chair moulds, wicker stools, etc..pls contact Sino.

Contact: Cina

export@sinomould.com