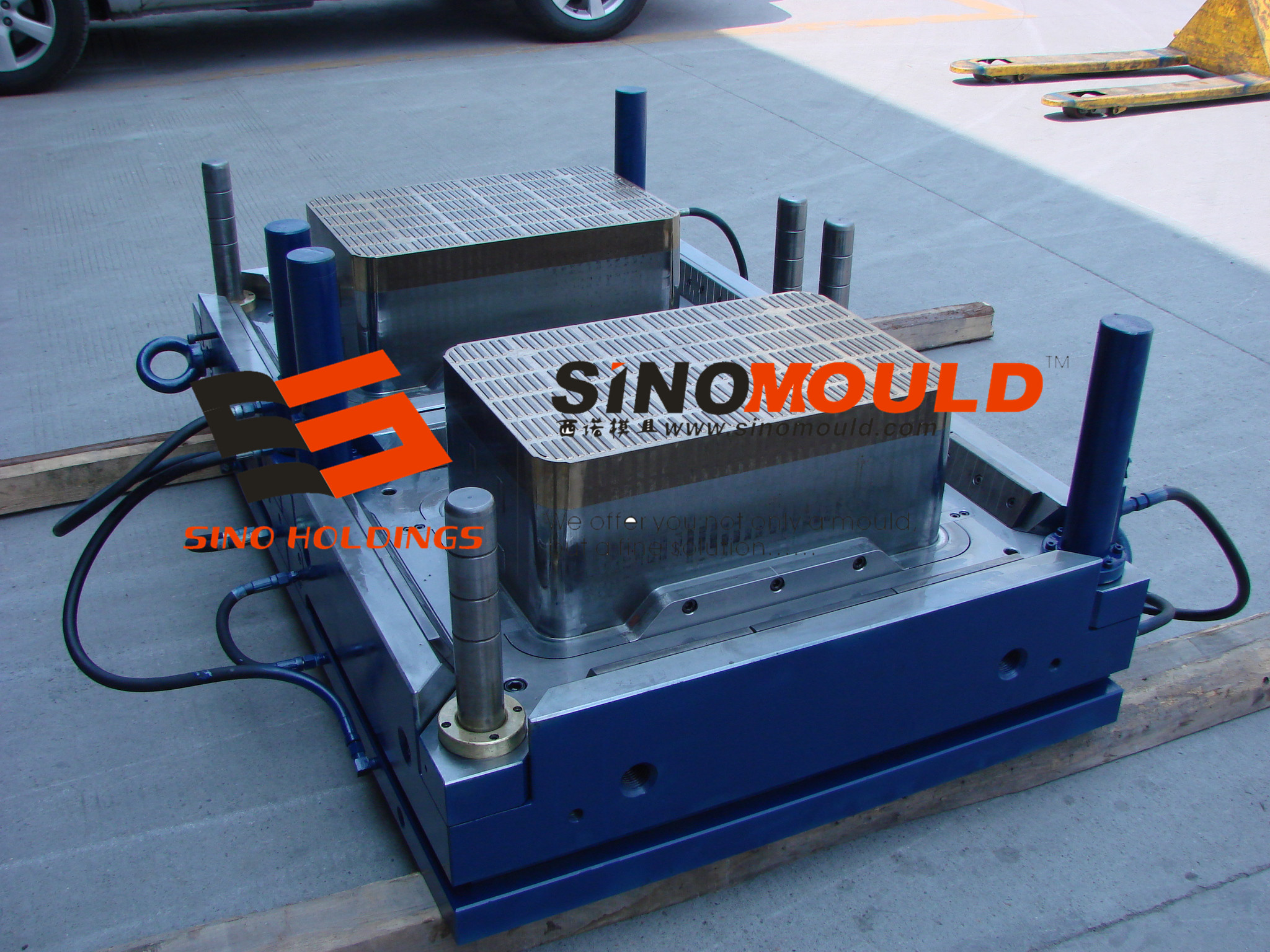

Sino Holdings group is one of leading plastic crate molds manufacturerin China. We have manufactured more than 2500 sets different plastic crate mold for our customers from company establishing. It is a wide range plastic crate molds, such as coca cola plastic bottle crate mold, industrial crate mould, vegetable crate mold, fruit crate mold, fish crate molds, plastic bread crate mold, milk crate mold, foldable crate mold, one off thin wall crate molds, double wall injection crate molds, two side stackable crate molds, etc.,

With past years, Sino has good plastic crate mold cooperation with German and Italy customers, has accumulated and updated many times for advanced plastic crate mold design and crate mold tooling.

Especially we have done many 2 cavities and 4 cavities crate mold with fast cycle molding cycle, min. we can get 15s for our one off crate molds. And for cola bottle crate mold, we design bottle crate mold with 4 side angle lift design and 4 sides handle with hollow on the 4 side wall. With such plastic bottle crate mold, we can develop with 2 cavities with crate mold cycle time 35 seconds with automatic dropping down.

How to make sure high quality crate mold? A good crate mold should be:

*long crate mold life with high quality mold steel

*crate mold easy injection and fast crate mold cycle time

*air venting solution system for crate molding

* Special hot runner system filter design for recycled material

*insert interchangeable system for crate mold

*advanced crate mold design like cooling system, demolding system…

If you are looking for top quality plastic crate molds manufacturer in china, pls do not hesitate to contact with us. We convince that you will find high cost performance plastic crate molds in Sino.

Martina

Skype: sinomould-17

Email: export@sinomould.com

Phone/whats APP: 0086+15215807221

Les gobelers aeriens et tasses de PS deveinnent le plus en plus populaire sur le marche. Dakumar est specialise pour offrir la solution de toute la ligne de production du gobelet aerien, qui inclut le moule du gobelet aerien, la machine d’injection du gobelet aerien et les machine d’auxiliare.

Pour fabriquer le gobelet aerien, les equipement principaux sont moules et machines. SINO MOULD a rich experience de faire le moule du gobelet aerien de 2 cavite, 4 cavite, 6 cavite et plus dans l’avenir. Differente cavite est selon de la demande de quantity de notre client. Par example, avec 6 cavite, le volume de production est pres de 2700 pcs chaque heure. Et pour la differente cavite du moule de gobelet aerien, la machine d’injection est different, par example:

Pour moule de PS gobelet de 2 cavite, on utilise DKM180T machine d’injection.

Pour moule de PS gobelet de 4 cavite, on utilise DKM250T machine d’injection.

Pour moule de PS gobelet de 6 cavite, on utilise DKM350T machine d’injection.

Et si vous avez besoin de la production de haute vitesse, on a aussi la machine de haute vitesse pour vous choissir, notre 5H machine 200HH ou 300HH. Le temps de cycle pour normal machine d’injection est 8-10s. Mais dans notre machine de haute vitesse, le temps de cycle, on peut arriver 6s a 8s. Voila vous donnez le haut volume de production.

Aux clients qui commencent un nouveau projetde fabriquer le gobelet PS ou gobelet aerien, la plus importante question est comment commencer et utiliser l’usine plastique est ce qu’ils se soucient. Mais avec l’aide de Dakumar, vous n’avez pas besoin d’inquieter cela. On peut vous envoyer un ingenieur pour vous aider, installer la machine,essayer le moule. On peut aussi former votre ouvriers. Alors,

Si vous commencez de zero, vous aussi peuvez utiliser notre machine apres notre ingenieur reste chez vous pour 10 jours.

Dakumar deja offre le moule et la machine a plus de 50 pays et aider plus de 100 clients commencer une nouvelle entreprise de toute la ligne de production de gobelet aerien, si vous avez besoin les details, me contactez par what’sapp /wachat:0086 15215807160 ou e-mail:export@sinomould.com. A la meme temps, notre website pour moule est: www.sinomould.com pour la machine est: www.dakumar.com .

Mlle Corine

Sino Mould, as a professional mould manufacturer, we have made lots of thinwall food container moulds. Mature mould design of thinwall food containermoulds,the demolding system can use stripper, air ejector, side air etc

according to the products. Good cooling channel achieve the short cycle time, and it also can add the beryllium copper to reduce the cycle time due to better heat conductivity.

Round thinwall food container mould

Raw material: PP

Wall thickness: 0.55mm

Usage: fast food packaging

Core and cavity steel: S136 stainless steel with HRC45-48

Guarantee mould life: 3 million shots.

Injection gate: full hot runner point gate

Cycle time: 6 seconds

Dakumar high speed injection molding machine is more suitable for thinwall products, accumulator can make injection faster, and high speed machine can achieve mould opening, ejection and charging at the same time.

For after-sales service, if any parts damaged due to the quality, we will send new parts for free during one year. If you are new in this field, SINO isyour best choice, we could offer the whole production line for you, and we will send engineer to your factory to help and teach you.

If you have any interests of thinwall food container mould or thinwall container production line, welcome to inquiry.

Posted by Erin

Email: export@sinomould.com

Whatsapp: 008613616760952

Skype: sinomould-10

nte et apres la vente.Cela laisse notre concepteur plus facile de dessiner plus meilleurs moule pour notre machine, parce que toutes les deux enreprises sont pres. Si on a des questions, les techniciens peuvent discuter directement.Si vous avez des questions pendant la production, on peut vous offrir les commentaires directement. Vous n’avez pas besoins de

Toutes la ligne de production plastique, SINO MOULD & DAKUMAR sont professionnel dans le domain de vous peut offrir divers type de toutes la ligne plastique. Pour le moule de caisse et la machine d’injection de caisse, on a deja rich d’experience d’offrir plus de 100 different ligne de caisse.

On a des experience de fabriquer moule de caisse plus de 30 annne, donc, on peut suggerer ou offrir notre client les meilleures solutions et plans selon les fonds de notre client, on sait la quelle type et machine il a besoin d'acheter d'abord.

L’acier pour moule de caisse, on peut utiliser de P20 a DIN2344, on aussi peut utiliser les partieavec cuproveryllium; system de canal chaud est le marque de nous-meme ou les specials. Pour la conception de moule de caisse, c'est important de dessiner une super et ferme moule pour utiliser long temps.

Et le system de refroidissement, c’est meilleures de le dessiner droit, ou laisse chaque circulation de refroidissement le moins le meilleure.

Avec machine d’injection de caisse, le moteur electrique de notre Dakuamar machine d’injection est professionnel pour long temps travail. Il a grand et evident advantages est economique d’energie.

On fabrique la machine utilise les pieces detachee de connu marque et notre machine a haute precision, alors elle est bon pour le moule de caisse, On peut avoir moins temps de cycle. Alors pour les caisses standards, le temps de cycle est 30s. Pour les caisse de parois fin, il a justement besoin de 15 seconds.

On est profesionnel d’offrir haute qualite de toute la ligne de production de caisse, si vous etesinteressee a notre moule et machine, n’hesitez pas me contactez, svp.

Mlle Corine

What’sapp/wechat:0086 152 1580 7160

E-mail: export@sinomould.com

There are more thanthousands and millions of disposable thin wall container are consumedby consumers all over the world,why there are so many thin wall container wereconsumed in the market ,that is the fast food restaurant and ice cream shop,toomuch consumption.

Actually,the mostly are fast food thin wall container are made by polystyrene ,foam ,if it is PP food grade container,usually we produce from thin wall container mould,usually ,the PP thin wall fast food container are occupy90% of the market.we are professional maker specialized in offer thin wall container production line. we offer high quality thin wall container mould and machine.

PP fast food container/thin wall container is a low cost product , so usually , manufacture can get profit fastafter start production . because high speed machine produce the thin wallcontainer ,it is very fast.only with high speedproducing ,that is with fast cycle time . take one of our thin wall box as anexample . 250ml thin wall container , the cycle time is about 5 to 6 secondsper shot . mould temperature 5-10 normal water . usually , the thickness of thePP fast food container is no more than 0.5mm . the thickness is hard to fill .thatis why thin wall container mould need high speed injection machine for massproduction . we are professional high speed machine as well thin wall container mould manufacture in China .

We can offer you suitable high speed machine to product thin wall container box .

What suitable high speed injection for produce thin wall container shall be .

1)High speed injecting .

2)Low pressure injecting.

3)Low temperature injecting .

If you have new project about thin wallcontainer or high speed injection molding machine ,welcome to contact me .

Posted by Selinda

E-mail :export@sinomould.com

Skype:sinogroupe-selinda

Whatsapp :0086 15858629913

SINOMOULD is professional in making all kinds of plastic crate mould. With many years’ experience in plastic crate mould, we have a series of tooling standard for the China plastic crate mould which will reduce the delivery time.

With reasonable tooling technology, applied Fidia high precision CNC milling center to make smooth parting line on product surface, especial handle parts. And good dimension tolerance is greatly helpful for mold matching process and balance wall thickness on double wall bottle crate mold.

What’smore, we have establish a special team to make the plastic crate mould, this is no need for your to worry about the mold design, mould tooling process, mouldm aintenance. Also we have introduced many famous brand tooling machines from Japan, Germany, Italy.. Which will be ensure with size of the crate moulds.

For the hot runner systems, we always use our own brand Anole hot runner system with German heating elements. We will take care of both mould and hot runner after sales, so you do not need to worry about the hot runner problems.

We also could provide the turkey solutions for the Crate Project, which including the crate mould, injection molding machine, and any other auxiliary machines.

If you are interested in the Plastic Crate Mould, do not hesitate to come to our factory, we are devoting to offer each customer with the best mould quality and service.

Postedby Amanda

CellPhone/Whatsapp:0086 13867653757

Skype:sinogroupe-61

E-mail;export@sinomould.com

Plastic chairs have been an essential household product in thecurrent life. How to make a good and high quality plastic chair mould ? Welcometo Sino ,we are professional plastic mould maker. Especially in plastic chairmould making , we have made various kinds of chair, like rattan chair , handlechair, beach chair , air assisted chair , PC chair etc.

Howto make a plastic chair mould ?

1.Mould steel are usually used P20 or 718

2.Gate: 90% are used edge gate

3.Ejector way: pin ejector, automatic ejector with robot

4.Surface treatment: polishing, leather, leather area

5.Surface inspection:

Bhave: not pull line.

Flying edge: the foot of the chair, theseam seam, because of bad exhaust, easy to appear flying side.

Superpositio: More than 10 chairs - do nottilt the superposition of two superimposed chair foot distance should notexceed 60mm, and after the superposition of easy separation

(superimposed reinforcement generallylocated under the seat):lighting brightness.

Strength: white hat (because the lightingis not good).

Forthe plastic chair injection machine , according to our experienced, it’ssuggested to use DKM650T machine , it’s depends on the chair product weight.The weight smaller than 2500g, we suggest to use 650 tonnage machine , ifbigger one , can try 780 tonnage machine, and some special chair , need morethan 1000 tonnage machine with lengthened nozzle.

Ifyou are looking for a good plastic chair mould maker , please kindly contact us,we will give you the best solution .

Rose:

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: live:sale66_5

IML system, one of the popular production lines in summer, have developed more and more large in plastic injection trade.We use for ice cream production line, food thin wall container production line and so on.

IML production line includes thin wall mold, high speed injection molding machine, robot, IML converys and some assessories, such as water chiller, auto loader, air dryer.

A total IML plastic injection molding system will take a lot cost. So usually, investors will choose much competitive price from supplier.

Sino Holdings, one of the professional plastic injection molding solution supplier in China, have more than 15 years for providing different kinds of plastic production line all over the world. We have mold for sale with injection molding machine. We aim to help clients for a turnkey plastic injection molding solution We ever offer chair production line for Venezuela, offer auto parts production line for Iran.

We have engineer can give you full set of IML production line and help clients from zero.We can send our engineer for training in your factory and teach one by one step.

At last, any plastic injection molding project need our help, welcome to our factory for further discussing, we will offer you a satisfited solution.

SINOMOULD has rich experience in makingplastic cap injected moulds , such as,anti-theft cap mold, flip top cap mould, bowknot cap mould, water cap mold,shampoo cap mould, bounce type cap moulds and so on. Each month, we exported world market about 20-30 sets plastic cap injectedmould.

We choseS136, Stavax ESR 136 made in ASSAB, withHRC 45-48. This mold steel will prolong the mold guaranteed life 1M. For themedical cap molds, we could specially deal with mold material with higher hardensince medical cap could not use oil but also suffer high clamping. And thissteel will make cap molds high polishing.

Inaddition, we had experienced plastic cap mold team. In mold design, we willoffer optimal cooling system and air venting system. And during cap moldmanufacture, each process finish, the mold part will through bridge coordinatemeasuring machine to check the precision. What’s more, our machine toolingequipment has Japan Shaddick, Italy Fidia, and so on. Take advantage of highprecision equipment, our whole mold delivery time could ensure about 45days.

Anyquestion regarding to plastic cap injected mould, please feel free to contactme and also welcome to visit our factory.

Snow

export@sinomould.com

Les Dakumar machines d’injection de moteur electrique sont utilisee largement dans ledomaine de toute la ligne divers de plastique avec moule d’injection de haute qualite,system de robot a haute precision et divers machine d’auxiliaire.

Dakumar entreprise a deja offert notre client plus de 870 sets solutions de differente toute la ligne de production plastique.On est professionel d’offrir la plus meilleuresligne dans votre cote avec notre service a temps et notre operation de simulation avantd’expedition.

Grace a Dakumar & SINO MOULD(toutes les deux sont notre meme marque), On sait bien

Mould d’injection et machine d’injection. Cela nous aide bps dans le domaine d’offrir toute la ligne de plastique. Alors on est specialist pour le service avant la vente, pendent la vente et apres la vente.Cela laisse notre concepteur plus facile de dessinerplus meilleurs moule pour notre machine, parce que toutes les deux enreprises sont pres. Si on a des questions, les techniciens peuvent discuter directement.Si vous avez des questions pendant la production, on peut vous offrir les commentaires directement. Vousn’avez pas besoins de communiquer avec plusieur fournisseur.

Sauf toute la ligne de production plastique, on aussi peut offrir le service de construire une nouvelle usine de zero. Il n’y a pas de problem de vous offrir conception juste d’usine, ligne d’eau et d’air.

Comme toute la ligne de production plastique, on peut offrir notre client les differentes genres ci-apres:

Toute la ligne de production de la plateau industriel

Toutes la ligne de production de IML pour pot de peinture

Toutes la ligne de production de chaisse

Toutes la ligne de production de table

Toutes la ligne de production de preform

Toutes la ligne de production de PVC contuite

Et etc.

Avec notre meilleures performance de notre moule et machine d’injection, je suis sure pouver vous offrir toutes la ligne de production plastique de haute qualite. Si vous etes en train de trouver une fournieeur, n’hesitez pas me contactez.

A la meme temps, vous pouvez visiter notre website: www.sinomould.com pour moule/ www.dakumar.com pour machine d’injection.

Mlle Corine

What’sapp/ wechat: 008615215807160

E-mail: export@sinomould.com