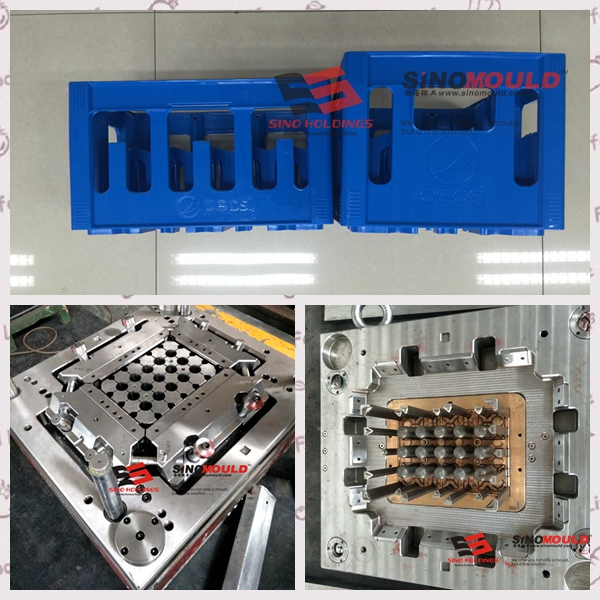

From 20 years ago, Sino team stands on the forefront of beverage crate molding in China. SINO MOULD brand means premium plastic crate molds- 12 bottles beer crate molds, 24-bottle wine crate mold,glass bottle case molds ect..

Why SINO can be Cola Moulds Vendor, Pepsi Crate Moulds partner and Schoeller China partner?Because our team prefers to design and manufacture good quality bottle crate molds to meet customer requirements.

During design, we pay attention for best cooling system torealize perfect cooling effect. And suitable crate mold structure, hydraulic stripper structure or puller rod ejection, to fast cycle time and increase mass production quantity. 2nd, reduced product weight is taken into consideration when we design glass bottle crate to get lighter-weight bottle crates. Our customer decrease production cost and increase their competitive ability.

With reasonable tooling technology, applied Fidia high precision CNC milling center to make smooth parting line on product surface, especial handle parts. And good dimension tolerance is greatly helpful for mold matching process and balance wall thickness on double wall bottle crate mold.

Cooperation with Sino Mould team will be your good choice for high level plastic bottle crate molds. And we also provide matching molding equipment to start your crate production line, like Dakmuar brand injection molding machine which can realize mold opening and ejection at same stage, and tailored design for cooling system on machine. Welcome your down visit and contact for your target plastic crate molding line.

Posted by: Ms. Helen

Email: export@sinomould.com

Whatsapp: 0086 15858625783 ( IMO no. / wechat no.)

Skype: sino.group10

All most of the families have juicy machines, because the juice cost very expensive in the shop and not natural . have a juicer machine will help them save a part of cost in daily like. In our customer group, they will purchase plastic juicer machine mold from us, make different models to suitable for more and more consumers requirement.

There are difference to the juicer machine price, from USD10 to USD2000, etc. We will customize different plastic juicer machine mold for them. Juicer machine is not similar to normal house appliance, Most of the juicer machine installed by many spare parts, so it has high requirement to the precision. Big tolerance process will affect the parts assembling and juicer machine quality.

Every year, SINO will help many customers offer fine injection solution, develop product structure. We are not only a mold maker, who make molds based on customer samples or designs. But also offer the best suitable injection molding solution. Only in this way, customer will get the biggest profit from us.

If you are looking for plastic juicer machine mold supplier in China.

If you have some idea about developing your products.

If you want to upgrade your production factory.

Welcome contact us freely. You need our professional.

Sales engineer: Candy

wechat & whatsapp: +86 158 5868 5263

email: export@sinomould.com

In our plastic injection trade, overmolding is one of technologies to achieve double color injection, while it hasa little different with double color injection.

Overmolding is a technology which injectionwith two different material. For example, one of our customer usually use PCand TPE for over molding air conditioner button. It need two mold. One is forPC products and the other is for TPE products.

When PC mold injection the products, weshould take them aside waiting them for shrinking. Often, we will have one dayfor them to shrink. Then we test the dimension is correct or not. Because themost significant thing for over molding products is size control.

After confirming the dimension, we willstart second injection--TPE injection. During the TPE injection ,we should paymore attention to the fitness of two material. Otherwise we could easy to separateone material from the other. It will be a small problem. Some clients will add adhesion agent in the material. I think it could be one way to solve this problem.

Anything about over molding or need overmolding service, welcome to contact and discuss with me. Snow will be waitingfor you in our factory!

Snow

Sino Mould is a professional plastic cap mould maker in China, we supply different types flip-top cap moulds, water cap moulds, spray cap moulds and so on. For the flip-top cap mould, our market is all around the world, from South America to Middle East and Africa market. We make multi-cavity flip top cap mould with autoclosure solution and fully hot runner sytem.

For the flip-top caps, which are widely used for the packaging industry, such as shampoo bottle cap, washing agent bottle cap, sauce cap and other bottle package. It should support for the seal until one bottle liquid finished completely. During the flip top cap design, we must make sure the strength for the cap close and open, cap fitting with the bottle smoothly, top cap fitting with the bottom part properly and easily opening.

We make the flip top cap mould with 4cavity, 8cavity, 16cavity, 24cavity, 32cavity and so on, with S136 stainless steel material for the core and cavity insert interchangeable. The mould could be designed with cold runner system, or hot runner system, or semi-hot runner system, according to the product shape and invest budget. With optimized design and reasonable moving structure, the plastic cap mould could run fast.

Sino Mould could support for plastic flip top cap mould and completely solution for cap injection molding, offer with plastic cap mould, injection molding machine, additional machines and technology support. If you need more information, please do not hesitate to contact me. We are ready to offer you high quality equipment with best service. Thanks.

Post by Miss Celina

Email: export@sinomould.com

Whatsapp: 008615257606120

If you are looking for Chinese top supplier with favorable and economical syringe complete production line solution, SINO HOLDINGS GROUP could offer you syringe complete production lines solution.

The mainly equipment of syringe line as follows:

Injection molding machine;

Moulds;

Assembling machine for Barrel, Plunger, Gasket, hub,needle hat to whole syringe;

Raw materials PP/PE/TPE/PVC;

Printing machine and package machine and EO sterilization;

Dust-free workshop with 100000 grade level.

Tell us your detailed requirements for the following points:

pThe disposable syringe type you are planning to produce, it will be better if you

pCan send us pictures.

pThe disposable syringe parts you would like to manufacturer. Normally, disposable syringe consists of 5 parts: Barrel, Plunger, Gasket, hub, needle hat. (Gasket and needle we suggest purchase from supplier)

pThe volume ranger of disposable syringe you are going to produce, 1ml, 2ml, 5ml, 10ml, 20ml…

pYour expected disposable syringe production capacity for each volume.

pYour plant working time, how many working days in a month, how many working hours in a day.

If you have any demand forsyringe complete production line solution, please feel free to contact us. SINO can give you more support than machine or mould.

Contacted person: Miss Nancy

Email: export@sinomould.com

Skype: sinomouold-01

Wechat/WhatsApp: +0086 137 5867 9372

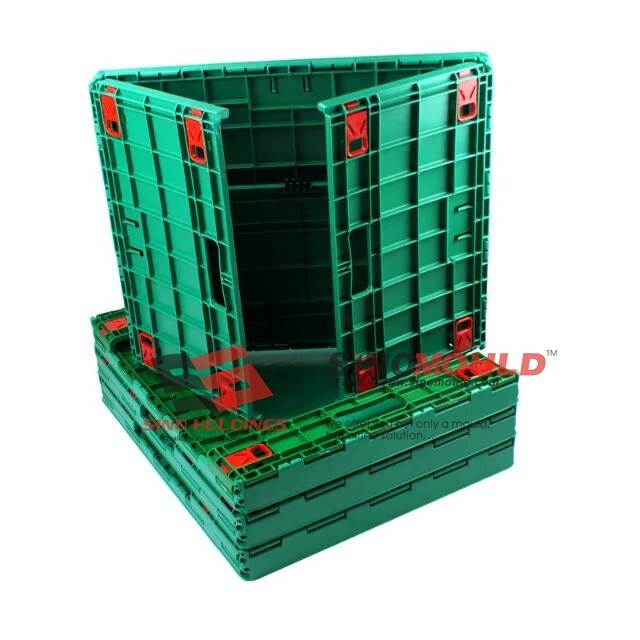

SINO Holdings Group supplies huge quantities of various foldable crates to all over the world. The manufacturing of foldable crates are including 4 series, A series, B series, C series, Dseries. All the foldable crates innovated with word logistical standard. They combined the advantages of save transportation cost, easy installation and easy to handle.

Collapsible plastic crates are strong and resist rough treatment. They are easy to fold sown and comfortable to grip,facilitating swift, simple handing. Such our C series, I will list in 6 points:

Cross Stacking Feature:

The bottom of the folding crate SINO design, can accept stacking in various direction. It accepts both vertical stacking, horizontal stacking, and also cross.

Easy Assembling

Can accept easy handling of assembling and disassembling,only by click in and pull out.

Easy Foldable and Compact Spacefor Storage.

Save 80% of space: only when use it, you can open the four sides, and clip them together by lock. In

this way, you do not need many spacefor the stock of crate itself.

Lid/Without lid option

You can choose with Lid and without Lid.

Various Optional Version forEach Size

SINO foldable crate offers customer with various optional version to meet different customer requirement. You can chose from open version.

Wheel Optional for EasyHandling

Strong wheel optional for size above 600*800 version, easy handling.

If you are interested in the foldable crateproject, welcome to contact us in your feel time.

Ms.Amanda

Skype: sinogroupe-61

Cell Phone/Whatsapp: 0086 13867653757

E-mail:export@sinomould.com

For perfect plastic thin wall box turnkey solution, we have accumulated rich experience on plastic thin wall box molds making and related high speed injection molding machine manufacturing. So if you are searching for thin wall box production line supplier in China, Sino will be your best choices.

1.About plastic thin wall box products, we made 100ML to more than 20L volume, shape with round, square, rectangle and oval etc; the cavity number we made is usually 2cavity or 4cavity or 8cavity for thin wall container; the mold steel for core/cavity is S136 with hardness HRC 48-52. In order to reduce cycle time, we also advise our customer add Becu

2.About hot runner, we usually use Anole hot runner system with German heating elements. Anole is our subsidiary company; we are also responsible for its quality.

3.About injection molding machine, we recommend our customer use DAKUMAR high speed injection molding machine. This machine is designed with accumulator to realize high speed injection. Besides, it has the function of 3axis linkage to realize material charging, mold opening and ejection at the same time. It shortens substantially cycle time. For example, cycle time reach 3.6s for 4cavity ice cream box mold with 0.4mm thickness.

4.About accessories assembling fittings, we advise as below:

4.About accessories assembling fittings, we advise as below:

Plastic raw material auto loader; air compressor; water chiller; top enter robot from Italy and conveyor belt etc.

5.About our after sales service, Sino give one year warranty and all life time service for engineering, if you have special requirement, we can send our professional engineer go aboard to help customer install machine, test mould, employee training....

If you want to set up thin wall box production line, please don’t hesitate to contact us. We offer you not only mold and machine, but also a fine solution.

Martina

Email: export@sinomould.com

Whatsapp/ wechat: 0086 15215807221

Garbage bin production line, household dustbin production line, dustbin series mould manufacturer

SINO HOLDINGS GROUP could offer customersIndustrial Garbage Bins& Household Dustbins Production Line,we have the confidence that we are your most suitable bin moulds manufacturer in China. We have garbage bin moulds 1L,5L, 10L, 15L&20L household garbage bin moulds. 90L, 100L, 120L, 240L,360L, 770L&1000L garbage bin moulds.

Garbage bin mould with moldmax for high speed injection, high standard garbage bin mould. During the past 11 years,SINO has delivered a lot of garbage bin moulds to all over the world, such like Brazil, Spain, Mexico, Israel, Italy, France, USA…

For production line, we could offer you garbage moulds, injection molding machine, auxiliary equipment, etc. forgarbage, we recommend customer use DAKUMAR Servo Motor injection molding machine, we have Injection molding machine size from 50T to 4000T, servo motor machine can save 20%-80% energy. For auxiliary equipment, we could offer customers auto loader, air dryer, chiller, mixer, crusher, etc. we will choose the most reasonable equipment for you.

If you have any demand for Industrial Garbage Bins& Household Dustbins Production Line, please feel free to contact us. SINO can give you more support than machine or mould.

Contacted person: Miss Nancy

Email: export@sinomould.com

Skype: sinomouold-01

Wechat/WhatsApp: +0086 137 5867 9372

Sino Mould Co.,Ltd is the world famous laundry basket and household commodity moldmanufacturer in Southeast of China. Every mold project holds the principle of meeting customer complete satisfaction.

Laundry basket have storage box, containers, food box, laundry basket, drawers, icebox, kitchen ware, etc. for commodity molds, we can offer customers high quality and fast cycle commodity molds can help you make fast and high return business investment.

Every year we export nearly 1000 sets molds to the world market, there are over 300 sets is laundry basket and household commodity molds. Sino team place importance in design and analysis QC control, our designers spend more effort in the product design and mold design.For some newly developed projects of customer, designers making mold flow analysis for studying the condition of mold running.

Sino is keen in offering world latest injection technology solution, in order to achieve the most cost effective, high performance, energy saving and environment friendly molding solution.

If you have any demand for laundry basket and household commodity mold, welcome to contact us. We are looking forward to growing shoulder by shoulder with you!

Contacted person: Miss Nancy

Email: export@sinomould.com

Skype: sinomouold-01

Wechat/WhatsApp: +0086 137 5867 9372

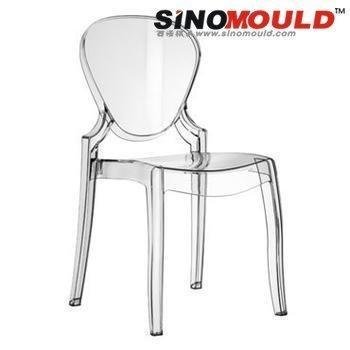

SINO HOLDINGS GROUP could offer customers chair complete production line, we have make different chair molds, such as daily use chair, beach chair, leisure chair, baby chair, gasassistant chair, PC chair, rattan chair.

For chair production line, we could offer customers chair molds, Servo motor injection molding machine, auxiliary equipment and technical supports.

SINO MOULD is Chinese top quality Chinese chair molds manufacturer, every year we produce more than 200 setschair, the cycle time is 35 to 40 seconds for high speed running cycle, and wehave interchangeable insert block different versions of chair backrest, theinsert can be easily replaced on the machine.

For Servo motor injection molding machine, we recommend customers use 650-1150T machine, machine tonnage based onmold structure. Servo motor machine can save 20%-80% energy.

For auxiliary equipment, we could offer customers auto loader, air dryer, chiller, mixer, crusher, etc. we will choose the most reasonable equipment for you.

In order to make much understanding ofyour plant, please fill our investigation list and when necessary. SINO willsend engineer before plant set up, for measuring, drawing and analysis thefloor foundation, and power condition. We are the best chair complete production line supplier.

Contacted person: Miss Nancy

Email: export@sinomould.com

Skype: sinomouold-01

Wechat/WhatsApp: +0086 137 5867 9372

SINO PK is a professional PET preform production line manufacturerin China.

SINO manufacturing PET preform mold for over 20 years, we are Chinese famous PET preform production line supplier, offer you high quality solutions with favorable prices.Every year we sells nearly 1000 sets moulds to the world market, over 400 sets moulds are belong to package moulds.

For PET preform line, we will recommend you the most suitable equipment for preform moulds, injection molding machine, auxiliary equipment, services etc.

Whatis the advantage to work your project in turnkey solution?

lEasily handing of your purchase

lAvoid arguing between different suppliers

lFast response for your doubt

lLess cost for paying service

lEasy QC control& inspection

lHigh matching of each equipment

lQuick delivery of all goods together

lClear responsibility of while project

lStrong design ability and uniformity

lProfit invery short time

lPrompt after-salesservice

lComplete database for future project.

Allin all, we could offer customer more than moulds and injection molding machine.Welcome to contact us if you are interested in PET preform production line.

Contacted person: Miss Nancy

Email: export@sinomould.com

Skype: sinomouold-01

Wechat/WhatsApp: +0086 137 5867 9372

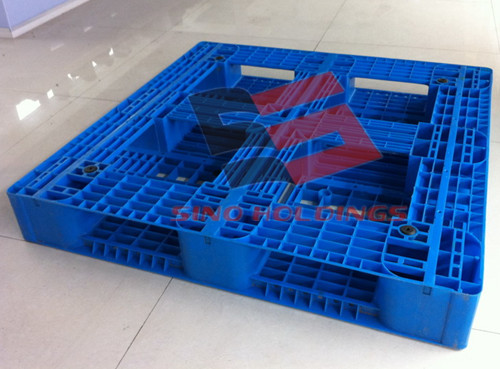

Withthe fast development for the logistic industry, Plastic pallet injection molding products become more and more popular, As a professional plastic pallet china mould maker, offering the finest plastic pallet injection molding line solution and plastic tray mould, welcome make detail consultation.

As the production conditions, storage conditions, the requirement of increasing the process control, quality management, because the wooden pallets in health status and unable to overcome the limitations of standard production, plastic tray, and quickly occupied a place. Has been widely used in machinery, electronics, food, medicine, clothing,etc. Compared with the wooden tray, plastic tray, integral sex is good health and clean, easy to wash disinfection, have qualitative light, in use without stinging, acid and alkali resistant, no mildew etc, its service life is 5 to 7 times that of the wooden pallets.

At the bottom of the plastic tray according to the shape can be divided into a lot of kinds, not every kind of tray is and all of the forklift truck can be used, some plastic tray can only use machinery forklift, some belong to mechanical generic manually. Whether suit for mechanical manual forklift general use, customer should see the main structure at the bottom of the tray, such as double or field words tray (due to the bottom of beam or plate) lead to manual forklift cannot enter, even into cannot be used due to is a fork in the middle of the tray, so consumers when purchasing plastic pallet must choose according to their actual usage, so as not to buy a tray is not suitable for their own products.

Sino SHG type plastic pallet can use for all the considering field. We make customize plastic pallet mould. welcome customer to make detail consultation. we ensure will offer our best service and products for you. Thank you for consideration.

Contact Tina

Whatsapp:008615067608197

export@sinomould.com