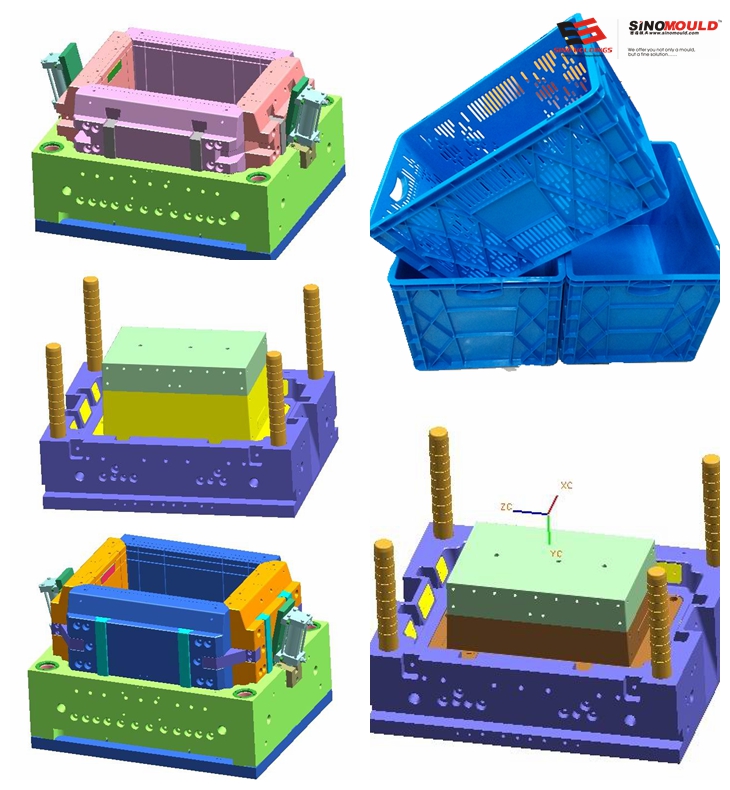

During competitive marketing,plastic crate manufactures need provide better quality crate with reason price.Soheight interchangeable crate molds, version interchangeable crate molds can realize produce different crates by one mold. It helps you meet local market with less investment on crate molds manufacture.

As this interchangeable crate molds need matching with different mold components to get required product. There is high demand of crate molds quality and dimension control, so you should find reliable interchangeable crate molds maker to avoid future cost. And you need prepare basic knowledgeon exchangeable crate molds’ main points.

Firstly, at mold design process, we need sure which mold components should be changed to get target crate heights or version. With pre-analysis, these crate product parting line, and ejection way-sliders and stripper or sliders and ejector pod will be confirmed. Then tooling technology choose, choose high precision CNC milling to make dimension tolerance 0.05mm for all main position and components,like slider base, mold cavity insert, wear plate, stripper groove and so on.Matching process, for K dimension position, it need carefully and experience workers. Also do marks on every mold parts to avoid mixing issue.

Compared with standard plastic crate molds,interchangeable crate molds are complex on tooling and matching process. SINO team aims to providing suitable solution from your sides, and realize long time stable running at your factory.

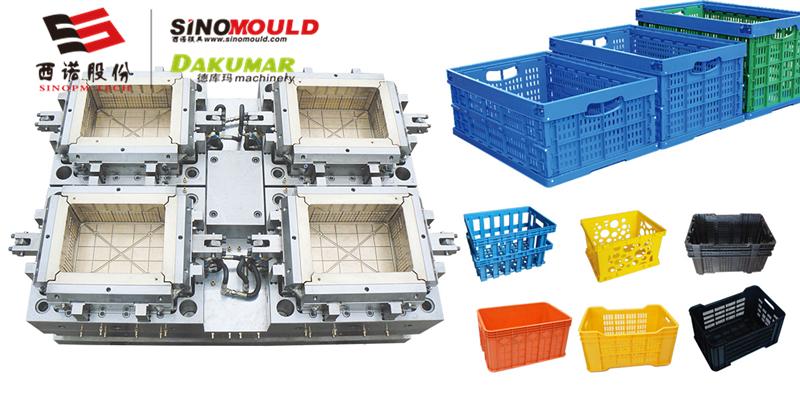

For the plastic crate mould, Sino has 25 years of production experience,

especially in fruit and vegetable crate moulds, bread crate moulds, beer

crate moulds, bottle crate moulds, foldable crate moulds and many others.

Most of the mold suppliers in China are trying to produce high-quality molds for plastic crates and provide them to customers. Each year, Sino will be

exported to pay more than 150 plastic crate moulds to foreign markets.

Plastic crate molds are the simplest and most common products for Sino, we

have our own mold making standards, and also have our own professional

R&D team and design team, which can reach the success of the first tryout.

Sino also have our own unique suggestions for hot runner with different structure.

For example, one cavity plastic crate mold has simple structure. For 2 cavities and

4 cavities plastic crate molds, we use double-sided hot runner.

At the same time, in order to shorten our production cycle of plastic crates molds,

we also specialize in the production of a standard shape, so that we can not only

guarantee the quality of plastic crates molds, mold can also save the production cycle,

while the accessories, we also prepare some of the necessary mold components,

because we have many such plastic turnover box mold orders every month.

If you are looking for a manufacturer of plastic crate molds, pls do not hesitate to

contact and visit us!

Компания SINO Mould занимается в пластиковой отрасли более

24 лет. У нас массовые опыты в производстве пресс-форм для

стульев. Мы предлагает пресс-формы для разнообразных стульев,

например,пресс-формы для стульев ежедневного использования,

пресс-формы для пляжных стульев,пресс-формы для плетеных

кресел,пресс-формы для офисных кресел,пресс-формы для стульев

для досуга,пресс-формы для летских стульев,пресс-формы для

стульев ротанга.

В сочетании с высоким кочеством пресс-форм для стульев,

высоким точным роботом,разнообразным периферийным

обрудованием и службы технической поддержки,

компания SINO предлогает серию готовых решений для стульев

с быстроходной службой.

Компания SINO Mould является всемирно известной компанией

по производству пресс-форм для литья пластмасс и достигла

отличных результатов в проектировании и производстве

пресс-форм для литья пластмасс. Каждый год более 200

комплектов пресс-форм для стульев экспортируется во все мир.

И взаимозаменяемая сменная пластина может быть легко заменена,

что позволитизготовить разные варианты спинки стула.

Цикл литья составляет от 35 до 40 секунд.

Мы советуем переселенцу работать с 650T-1150TТПА.

Тоннажность машины зависит от конструкции пресс-форм.

Мы можем предлогать ТПА и у нас есть опытные технические

инженеры и технические группы. ТПА с сервоприводом может

сохранить энергию 20% -80%.

Для периферийных обрудования,мы можем предлогать

бункер-сушилки,автозагрузчик,чиллер,дробилка и так далее.

мы выберем самое разумное оборудование для вас.

Если вы ищете хороший снабженческий торговец, который

может предлогать высококачественный и высокий точный ТПА и

пресс-формы для стульев, приветствует отправлять по электронной

почте и связываться с нами.

We are professional in making molding equipments for disposable plastic cutlery parts. When developing plastic cutlery molds, it is more profitable to make plastic molds with plastic spoon, plastic knife and plastic fork together. And it is very critical to make plastic cutlery parts molding in very fast cycle time. The plastic injection mold for disposable tableware can be in both round shape and square shape. If with semi hot runner, it is better to design mold in round shape, as the plastic material flow is more even and it is less runner waste.

Due to large quantity needed for disposable plastic spoon, fork and knife, the plastic cutlery molds should be designed with very good cooling channel, to make plastic cutlery molds achieve fasted molding cycle time. And compared speaking, we are recommend our high speed injection machines for high speed cutlery molding. Also it would be ok for us to make stacking spoon molds to keep high productivity.

Welcome contact us for our high speed injection machine and plastic cutlery molds. We located at Huangyan, Taizhou city. Very appreciated for your down visiting to us.

Sino Mould has rich experience in offering the best solution of PET

preform. And we already shipped 72 cavities PET preform production

line, 48 cavities preform production line, 3 gallon PET preform

production line, 5 gallon PET preform production etc to many

countries. For 5 gallon PET preform mould, it usually make into

1 cavity or 2 cavities. 1 cavity 5 gallon preform mould will be

designed into direct cone gate which need cut the gate tail manually

or can use robot to cut the gate and pick the preform out of the

machine automatically. We could recommend according to your requirements

to offer the most suitable solution for you. For 2 cavities 5 gallon

preform mould, it’s no need cut the gate because it will be designed

with hot runner valve gate.

1 cavity 5 gallon PET preform mould

Preform height: 725mm

Preform weight:750 grams

Core and cavity steel: S136 stainless steel made in ASSAB

Cycle time: 92 seconds

Suitable machine: Dakumar 450Ton PET injection molding machine

2 cavities 5 gallon PET preform mould

Injection gate: hot runner valve gate, no need to cut the gate

Can use robot to achieve automatic work

Cycle time around 100 seconds.

Suitable machine: Dakumar 650Ton machine.

If you are interested in making 5 gallon PET preform mould,

welcome to inquiry.

As soft drink is more and more popular in the world, cap quantity demand is also increasing accordingly. Sino Mould has rich experience in making muti-cavity cap mould, such like 48 cavities, 72cavities, 96 cavities. Annually, we ship about 100-120 sets of cap moulds, most of them are muti-cavity cap moulds.

Product Name: 72 cavities water cap with PCO 28mm

Mold size: 1320*620*759mm

Mold steel: S136 stainless steel with HRC48-50(ASSAB)

Cycle time: 7s while produce on our DKM-600HH high speed molding machine.

Product weight: 2g

Raw material: PE

Mold gate: Anole full hot runner

Guarantee time: 5 million shots, usually the mold life is 5-8 times more than guarantee time under the regularly maintenance and correct operation.

Mold structure: interchangeable core and cavity, it is easier for maintenance and repair.

Water channel: around core and cavity.

Delivery time: about 50 days

Mold inspection key points: sealing, weight, appearance (no flash and burr)

In order to meet your large quantity requirement for the cap, SINO MOULD offers you multi-cavity cap mould with short cycle time. In a word,we can offer you the turnkey solution, to achieve less investment brings more benefit. Welcome to contact with us for more details.

On fabrique bps de gence de moule de PVC raccord et a des experience plus de 25 annnee.

Le type de mould de PVC raccord est divisé en forme de Y, en forme de U, en forme de T, et etc.L'utilisation de notre PVC raccord est divisé en utilisation industrie, usage domestique, usageagricole et etc.

Notre moule de raccord est avec de bonne qualité.

PVC raccord pliable moule avec ф min. 32mm.

Cavités et noyaux en acier stavax s136 trempé avec HRC.48-52.

Utiliser deux fois d'outillage : outillage rugueux precision outillage trempé.

On utilise machine precise pour faire chaque process.

En même temps garder le moule solide et durable.

Pour fixer le glissoir, on utilis un bouchon pour s'assurer que la lame ne peut pas glisser vers le bas en raison de la gravité.

Course pour régulateur à coulisse course et prolonger la vie du moule.

Notre moule avec le meilleur service, pourrait vous offrir une solution complete: choisir la machine et acier approprié pour vous. Offrir une formation de technologie après la vente.

Si vous envisagez d'acheter le moule de PVC raccord, n'hésitez pas à me contacter.

Une célèbres fournisseur de la ligne de multi cavités préforme vous offre le moule de préforme et PET machine d'injection plus de 20 ans et nous pouvons aussi envoyer l'ingénieur au pays de nos clients pour le service après-vente.

La cavité varient de 16,32,48,64,72,96,144 etc., nous vous offrons le moule de préforme de multi cavités de haute qualité et longue durée de vie. Pour faire le temps de cycle de moule de préforme pouvoir être le plus court, nous avons développé la manière de refroidissement optimisée pour chaque noyau et cavité. On essaie de faire nos effort pour rendre la préforme moule pourrait maîtrise de soi, donc la stabilité est meilleure que les autres fournisseurs.

Nous pourrions vous offrir les moules de préforme de multi cavité, mais aussi PET machine d’injection et la formation.

1. formation dans Dakumar entreprise

2. envoyer l'ingénieur pour installer le moule et la machine

3. aider les clients à commencer la production de masse

4. Formation des travailleurs locaux d'apprendre l'entretien de base

Si notre client veut construire l’entreprise de la linge de préforme de multi cavités, nous pourrions vous aider à faire le dessin de bâtiment de l'usine. Définissez le suffisamment d'air, électricité, eau et etc.

Sino est fournisseur de moule de préforme multi cavités, nous pourrions vous offrir tous les équipements. Notre entreprise a riche expérience, si vous avez des questions, n’hésitez pas à mecontacter.

Are youlooking for the top quality Coca cola bottle crate mold in China? Are youlooking for the responsibility mold manufacture in China?

Welcome to Sino Mould Co., Ltd, the world famous plastic mould manufacturer in China, wehave rich experienced for making various kinds of bottle crate molds, usually,the coca cola crate contain with 12 bottles and 24 bottles.

Good Cocacola crate mold structure design is very important, it is the precondition of aqualified mold manufacture, Sino Mould company technical department have morethan 30 professional mold designers which given advanced design support, theyare mostly more than 8 years of work experience. As we know, the beer crate have many ribs onmolding, so the air venting and cooling system designing is very important!

Sino Mouldcompany can offer you the high quality beer bottle crate molds with high speedcycle time based on our very competitive price, our crate mould meet Europeanmarket demand to supply our worldwide customers.

24 hours hotline service before and after sales service, we have a very strong team tooffer the turnkey solutions, if you need any helpfor coca cola bottle rate mold serivce help, pls feel free to contact us, we are sure to offer you a fine solution.

Вы ищете хороший иопытный поставщик, который может

предложить производственную линию для ПЭТ?

В настоящее время продукты производства для ПЭТ преформ

являются все более и более важно на рынке во всем мире.

Компания SINO Mould представляет собой всемирную известную

компанию по производству пресс-форм для литья пластмасс в Китае.

Она имеет массовые обрабатывающая аппарат и токарные станки,

большая часть которого привезена из Европы, Италии и Японии.

Компания SINO Mould имеет больше чем 20 лет опыты в

изготовлении пресс-форм для ПЭТ.

Большой часть из клиентов любить купить пресс-формы для ПЭТ

и термопластавтоматы, спроектированный для литья ПЭТ преформ

из Китая.

Для пресс-форм для ПЭТ:

Нам можно поставить пресс-формы для ПЭТ с 8 полостью,

пресс-формы для ПЭТ с 12 полостью, пресс-формы для

ПЭТ с 24 полостью, пресс-формы для ПЭТ с 32 полостью,

пресс-формы для ПЭТ с 48 полостью, пресс-формы для ПЭТ

с 72 полостью и так далее.

Сталь:

1.Ядро и полость пресс-форм для ПЭТ представляет собой S136HRC40-44.

2.P20 принимается для плиты пресс-форм для ПЭТ, чтобы избежать

коррозии действенно и гарантировать долгую жизнь служб плиты.

3.Хорошая термическая обработка пресс-форм,которая убеждает

твердости компонентов.

Если вы ищете хороший снабженческий торговец, который

может предлогать пресс-форм для ПЭТ высокого качество и

высокой точности, приветствует отправлять по электронной

почте и связываться с нами.

Лилия

Sino mould is the world famous logistics plastic tray injection mould manufacturer. The key point of the culture is the responsibility to provide final customer best injection mould. With more than 25 years mould manufacture experience and technical research and innovation, Sino team already have more 1263sets technical intellectual property rights on moulds making .And we are always develop our production field and improve our mould quality, we trust with our support, customer would make big out put for the plastic tray.

Sino made tray mould production key point:

1.Stacking loading & static loading request

Normally Single face logistics tray has the stacking layer request, double face logistic tray do not have the stacking request, the height normally is 150mm.

2.Perfect angle for the mould design, it would relate to the plastic forming, and tray strength.

3.Before mould making, Sino team would analysis the tray product moldflow, ensure the injection point position and quantity, to make best molding service.

4.On the back side of the pallet,better arrange the antiskid pad design

5.To know more detail, welcome to SINO make detail inquiry.

6.…

Sino made logistics plastic tray mould design, fully consider customer investment request, realize high strong strength,easy demould structure and advance technical design. If you have some plastic tray mould project need to start or plan to invest plastic tray mould, welcome here, We will doour best to support you.

В настоящее время пластиковый тарстановится все больше

и больше популярными в обиходной жизни и транспорте

из-за его инновационной конструкции.

Это может помогать экономить более 50% место и более во

время перевозки и снизить расходы.

Поэтому все больше и больше людей начать употреблять

пластиковый тар на разнородные продукции.

Компания SINO Mould является всемирно известной компанией

по производству пресс-форм для литья пластмасс и достигла

отличных результатов в проектировании и производстве

пресс-форм для литья пластмасс.

И компания SINO Mould имеет массовые опыты в производстве

различные пресс-формы для тары: бутылочнвые тары,

тары для овощей, тары для молочных ящиков, пресс-формы для

складной тары и так далее.

Обратите, пожалуйста, внимание на следующие подробные

информации пресс-формы для тары:

1.Материалы и сталь пресс-формы

Обычно HDPE применяется для сырого материала,который

имеет высокая прочность и высокие сопротивление пластика

сжатию.

Если это одноразовое, вам можно использоваться PP.

Мы обычно делаем с сталью P20,718 и DIN2738,и переселенец

может выбирать сталь для пресс-формы тары.

2.Циклическое время

Один место:30s

Два место:45s

Четыре место:55s

3.Проверка точек

После наложение смещение не должно быть большим.

Проверять толщину и грамм-вес тары.

Мы профессиональная компания, которая делает различные

пресс-формы для тары, если вы ищете хороший

снабженческий торговец, приветствуеть отправлять по

электронной почте и связываться с нами.

Лилия