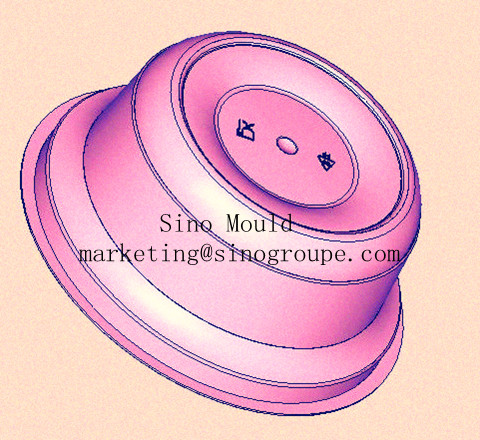

Sino mould can offer high quality plastic Traffic cone mould with:

1.high quality

2.competitve price

3.on time delivery

4.optimal cooling system

Product Name | Traffic cone mould |

Product material | PE,PVC,PA |

Core&Cavity Steel | P20,718HH,2738 |

Steel hardness: | HRC48-52 |

Mould Standard | DME |

Cavity Number | one/two |

Injection System | Direct gate |

Ejector System | Stripper plate |

Cycle Time | 50'' |

Tooling lead time | 60days |

Mould life | 1,000,000 times |

Quality assurance | ISO9001 |

Our Advantage | 1.High quality |

2.Reasonable price | |

3.On time delivery | |

4.Good After-sale service | |

5.Strict quality control | |

6.All the mould are automotic. | |

| 20 | |

Offer you | In-time response on mail, telephone calls |

In-time supply the quotation and mould designs | |

In-time communication on the technical points | |

In-time sending pictures for the mould machining progress and mould finishing schedule | |

In-time mould test and sample delivery | |

In-time mould delivery. | |

For more information please contact us. Contact: Ms Charlene Skype:sino.group03 MSN: export@sinomould.com Mail: export@sinomould.com | |

foldable crate mould,folding crate mould supplier,custom foldable crate mould,offer crate mould,

Plastic crate are widely used in electronic auto parts, electrical appliancesl, packaging, machinery, light industry, food, medicine, advertising, packaging, stationery industries.

But many users are headache about the narrow storage space, and want to find

a space save way; Now foldable crate can helps you solve the problem. Foldable crate is the ideal storage part that can be folded flat to a very small size, when required, and then immediately open the foldable crate to use.

Foldable crate can be widely used in Daily life, our work; Foldable crate can transport fruits, milk, vegetables, bread…Almost everything you want.

Foldable crate Feature: Non-toxic, odorless, moisture, corrosion resistance, light weight, durable, stackable, look gorgeous, rich colors and pure characteristics. Why choose Sino Mould foldable crate, because of the lower price, Long service life, convenience, and highlight injection technology.

SINO MOULD provides different size of foldable crate to meet clients’ requires from 400*300*150mm to 800*600*450mm.

If you have any interest of plastic foldable crate, please feel free to contact with me.

Contact:Diana

Mail:export@sinomould.com

Skype:sino.group01

Are you looking for good pet preform mould ? A lot of beverage manufactures are purchasing good pet preform mould from China, China PET preform mould manufactures supply good price , good performance PET preform mould. Sinomould is one of the leading Chinese preform mould manufacture. Sinomould supply customers 8 cavity preform mould, 12 cavity perform mould, 16 cavity preform mould, 24 cavity preform mould, 32 cavity preform mould, 48 cavity preform mould, 72 cavity preform mould and 96 cavity preform mould….. Sinomould not only provide customers a good preform mould, but also a fine PET packaging solution!

*Advanced structure is designed in base of German and Swedish preform mold;

*Core and cavity are made of imported nitrated steel in accordance with international standard;

*The excellent hot runner design assures uniform heating and improves the plastic product quality greatly;

*High efficiency is attained with water cooling at normal temperature;Mold ranges from 1 cavity up to 72 cavities;

Steel

1. Core and cavity are made of S420 material (Sweden ASSAB).

2. P20 mould plate, avoids corrosion efficaciously and assures long life service of the perform molds.

3. Good heat treatment of the components, which assures the hardness of components HRC48-HRC50

If you have some new project for PET Preform Mould and want to custom PET Preform Moulds. Sino Mould can offer you full set PET Preform moulding solution. If you feel interest, please feel free to contact me.

Contact: Ms Charlene

Skype: sino.group03

MSN:export@sinomould.com

Mail: export@sinomould.com

This article is mainly talking about Spoon & Fork Stacking mould, China Spoon & Fork Stacking mould design,China Spoon & Fork Stacking moulds,

China Spoon & Fork Stacking moulds tooling,China Huangyan Spoon & Fork Stacking mould maker,China Huangyan Spoon & Fork Stacking mould technology,China Spoon & Fork Stacking mould machine,China Huangyan Spoon & Fork Stacking mould price, China Huangyan Spoon & Fork Stacking mould quality,China Huangyan Spoon & Fork Stacking mould manufacturer,China Spoon & Fork Stacking mould material

Spoon & Fork Stacking mould material

Regarding Spoon & Fork Stacking moulds , usually we use we use Din1.2316 material or S136 material ,make sure the Spoon & Fork Stacking mould can be produced under high speed with long service life.

Spoon & Fork Stacking moulds making

We make Spoon & Fork Stacking moulds through 3 stage.First,CNC rough tooling, we will leave some tolearance for precision milling in this stage.

After rough tooling, we will make heat treatment to get the mould with higher hardness to longer the mould service life. After heat treatment, the mould dimension will change a little and also the shape, so we will use Italy imported FIDIA high speed milling machine to tooling the mould to make sure China Huangyan plastic fans molds with high precision dimension.

Spoon & Fork Stacking moulds design

We have our design team and R&D design department, so we have top design mentality to design Spoon & Fork Stacking mould design. We wil

make Spoon & Fork Stacking moulds mold-flow analysis to make sure the optimize injection system and cooling system.

Spoon & Fork Stacking moulds quality inspection

We have our own high quality cordinate bridge inspection machine to inspect the mould components before go into the next step.So we can make sure the mould dimension in a good condition.

For more information about Spoon & Fork Stacking moulds, please don't hesitate to contact with me.

Edited by Wendy Lu

Sales Engineer

Email:export@sinomould.com

Skype: sino.holdings.group-007

phone:+86-576-81106962

Injection mould is the most important molding equipment to injection product, its quality directly related to product quality. And its service life directly affects product cost. So improve injection mould quality and preventive maintenance and good, prolong the service cycle, is important to injection mould.

Because the product variety, plastic injection mold changing are more frequent in completing a production cycle, after process, mould also need rest , but in this period if you didn’t protect well, mould will become rust, and cause the product quality declining, high scrap rate.

Injection mould maintenance knowledge 1, processing enterprises should first vice mould to each equipped with resume card, documented, statistical its make and damage situation, can be found in what parts, components has been damaged, wear degree size, to provide finding and solving problems of information material, the products used material, in order to shorten the mould test time and improve production efficiency.

A pair of after good maintenance of the mold, can shorten the mold assembly, test drive time, reduce production failure, make production running smoothly, to ensure product quality, lower enterprise operating costs and fixed assets investment, then next time begin process, can able smoothly produce quality qualified products.

If you interested in this, you can contact me: export@sinomould.com .

Post by: Ophelia Chan

Sales engineer

Skype: sinomould-10

A mould need us to protect, it will have long life to produce more product.

1. Mould material

Different materials often have different mould life.

Material type, chemical composition, the structure of the organization is the comprehensive reflection.

(1) The use of material properties should be with high hardness and high strength and high wear resistance and enough toughness.

(2) The process performance should good.

2. The rationality of the mould design

3. Processing surface quality

Mould working parts and the surface quality of the wear resistance, resistance to mould fracture and the ability to stick with ability has a very close relationship, directly affect the service life of the mould.

The processing should prevent mould working parts surface with scar.

4. Stamping process

The actual production, the pressure of the raw material thickness tolerance parts of tolerance and material performance, fluctuation, the poor quality of the surface (such as rust) or not clean (such as oil) and so on, can cause mould working parts wear quickly, easy to lead bad consequences

All in all, the material, heat treatment, hardness, the rationality of the mould design, and mould process, the processing accuracy, the mold assembly, with a match is uniform and reasonable or not, all can affect the service life of mould.

Edited by: Ophelia Chan

Sales engineer

Skype: sinomould-10

Sino Mould is a thin wall bowl mould maker, thin wall bowl molds manufacturer, thin wall bowl moulds making company, Sino offers full set thin bowl molding solution to all over world customers.

Thin wall products are more and more used in our normal life. Thin wall mold can save a lot of plastic and decrease the cost. So, mould makers try to use thin wall tech in more field, suck like thin wall plate mould, thin wall bowl moulds, thin wall pallet mould, thin wall food container mould.

I would like to share one of our experiences in making thin wall bowl moulds.

Mould Name: Thin Wall Bowl Moulds

Mould Cavity: 4 cavities

Mould Size: 500x500x500mm

Mould Core and Cavity steel: S136

Mould Life: 1M

Ejection way: stripper

Hot Runner System: Anole Hot Runner

Suitable Machine: Dakumar 330T

Delivery Time: 60 Days

If you have any new project for thin wall bowl mould and feel interest about our thin wall bowl mold, welcome to send your product information for enquiry, also your down visit is welcomed.

Miss Summer

Skype: sino-mould02

MSN:export@sinomould.com

Mail: export@sinomould.comexport@sinomould.com

Web: http://www.cnmould.com

SINO MOULD is famous mould maker in china , we are Chinese industrial mould supplier ,offer industrial mould ,such as crate mould ,bottle crate mould ,pallet crate mould, traffic tool mould maker china ,we are the famous industrial mould maker in china

We have many years experience in making the large mould , which the air venting and the water way is important to the mould itself. While ignore the mould flow analysis and lack of this technology is also the shortage .our Sino Mould do the full advanced preparation avoiding the mould wrong work. Crate industrial mould is the featured product ,which we have the matured technology to deal with all the problems.

Normally, before mould setup,we will do the mould analysis and the discussion meeting about the mould design and the requirement of our customer,we will not let the misunderstanding happen ,we also use the unique and most suitable hot runner system,which is the brand our company create called Anole hot runner system, which have the maintenance agent in many countries, so our company have go into the International.

If you wish to custom the mould ,we are your best choice,if you wish to make the perfect mould ,we are your trusted friend. If you like to order the mould ,pls feel free to contact me

Sino Mouldis a famous China folding crate moldsupplier. Now we are trying our best to become the largest China folding crate manufacturer. Now recently, as a professional China folding crate maker, we put forward a new series of folding crate Chinese, totally four models of China folding crate.

The size of crate has always been a problem for crate importer. Now China folding crate, which can save a lot f space, can help importers solve this problem. Take a 400*300*230mm crate for example, before being folded, only 680 crates can fix in a 20' container. After being folded, 3060 folding crates can fix in a 20' container. Thus, you can put more than three times of folding crate in one container than common crate. So buying folding crate you can save 2/3 of ocean freight.

As an experienced China folding crate supplier, Sino can manufacture folding crate quickly for a container within a week. Now we offer four models folding crate Chinese mold with size of 400*300*150mm, 400*300*230mm, 400*300*330mm and 400*300*380mm.

Find interest in folding crate Chinese, contact Sino Mould.

Miss Cina

E-mail: export@sinomould.com

Skype: sinomould-13

MSN: export@sinomould.com

Foldable Crate

SHG is the large foldable crate manufacturer in China,manufacturing various foldable crates,foldable container,collapsible crates,Folding Container,Large Foldable Container,LFC Container,LFC Box,LFC Crates,collapsible crates, and deliver them to all over the worlds.

SHG foldable crate has more than 100 different types, they are including foldable crates, foldable container, collapsible crates and large foldable containers.

Sino Mould is SHG foldable crates molds suppliers, Sino Mould made more than 3 millions USD for SHG brand of foldable crate.

Posted by Lucy

Email:export@sinomould.comSkype:anole-hc-01

Posted by Lucy

Email:export@sinomould.comSkype:anole-hc-01