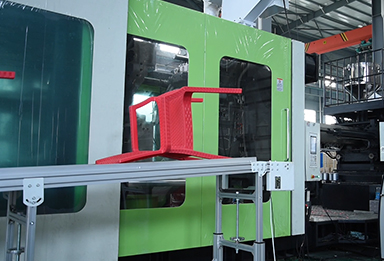

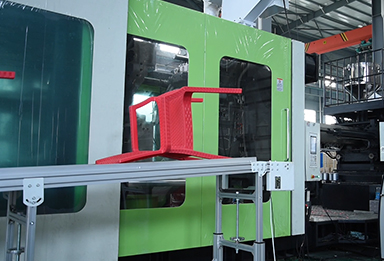

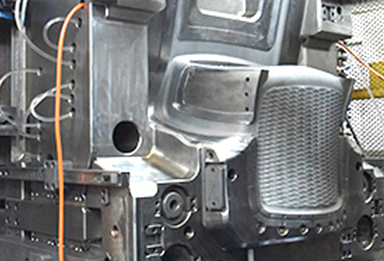

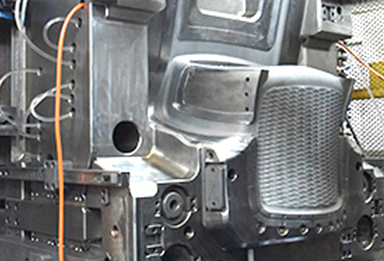

Gas Assist injection moulding is normally applicable for components in which there are thick sections. Gas assist injection moulding is able to reduce the weight and reinform the plastic components after its molding finish. It is widely applied for gas assist injection moulding in chair mould, table mould, automotive mould and so on. Sino made gas-assisted injection mould annully 100sets, and own our own equipment for injection with gas assist injection moulding technology.

Gas Assist injection moulding typical applications:

The gas flows into the path of least resistance in the thicker sections where the plastic interior is still in a molten state. Reduced in-mould pressures by up to 60%, and therefore reduced press lock forces enabling larger

The use of the gas injection moulding as a means of transmitting pressure uniformly throughout the moulding. mouldings on much smaller machines.

Reduced power consumption.

Reduced moulded in stress, and therefore improved dimensional stability with no distortion.