SINO MOULD has been specialized in manufacturing high-end home appliance mold more than 20 years with customers such like Fagor, Simens, Hitachi, Unionaire, Unitech, Voltas an so on. Annually our turnover is around USD 12 Million for home appliance mould. Besides, we are devoted to providing a complete home appliance molding solution from moldflow simulation analysis, product design optimization, mold design improvement, plastic parts production and its related metal, glass, elastomers purchase and assembling.

It is important to evaluate plastic home appliance part feasibility of its structure rationality, molding technology, mold making and each component assembling because if there are shortcomings or mistakes found in molding process, it will kill all efforts before. SINO Team owns R & D engineers whom had product industrial design capability and at least 8 years high precision molding experience. Hence, if you are in new home appliance development, we could provide you professional suggestion for various sides.

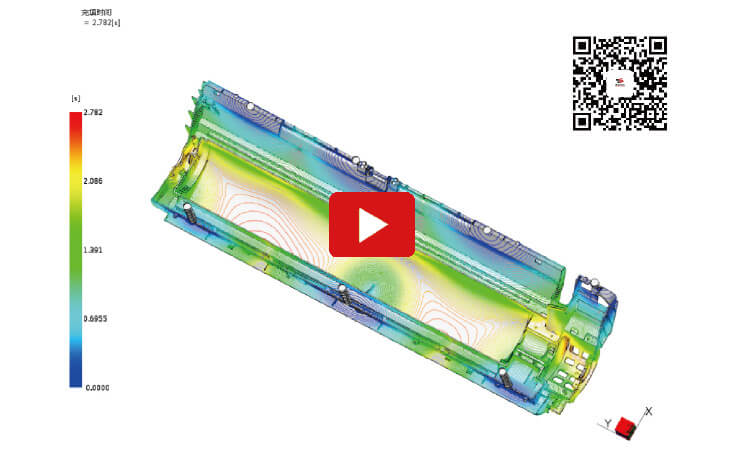

Besides, taking advantage of MoldFlow analysis software, SINO would provide a comprehensive mold making feasibility analysis report which contained injection gate location, gate type and quantity, parting line analysis, key dimension confirmation and so on. And according to the reports, we could make suggestion for improvement and also decide whether to use breathable steel in welding line or not.

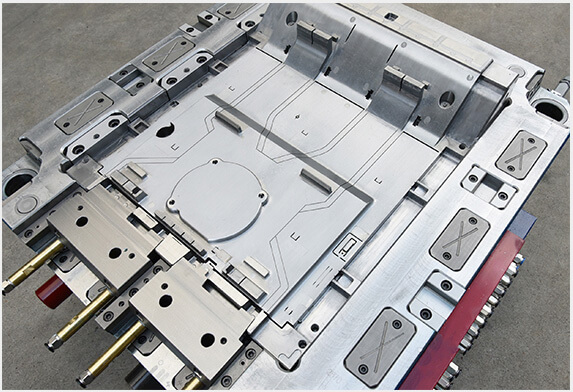

Usually home appliance plastic parts will be assembled with metal parts, but it is hard to control metal part tolerance. Hence, plastic part tolerance shall be controlled rigorously to ensure good assembling. SINO team will consider the structure of assembling area in advance. Meanwhile, high precision tooling equipment will be another key point for good assembling. That’s why SINO brought milling center (4200*1800CM) years ago which suits for large air conditional panel mold tooling, and tooling depth could be 600-800mm which suits for washing machine mold processing.

During each process of tooling, every mold parts finished must be passed to quality department to ensure the maximum quality pass rate. By using three dimension bridge inspection machine which tolerance 0.01MM, it could be strictly control all dimensions.

To ensure home appliance good polishing surface, SINO team applies the three steps polishing process. Use 1200# oil stone first, then 2500-3000# sand paper, and finally wool ball polishing.

SINO has our own testing department with more than 35 sets injection molding machines from 80 ton to 2250 ton. And each mold will be arranged for high and low pressure testing by at least 8 hours continues running.

SINO MOULD is engaged in making your home appliance molding more valuable by long-term cooperation. Till now, SINO MOULD has delivered various home appliance molds, such like air condition mold, refrigerator mold, washing machine mold, fan mold, TV mold and so on, which are reputed among customers. Thus, if you are looking for superior home appliance mold solutions, kindly contact us now.

Contact Us to Get Your Home Appliance Mold Solution