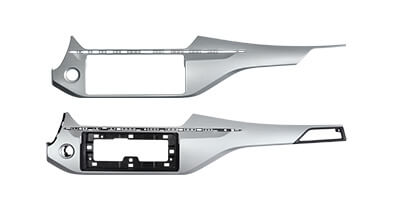

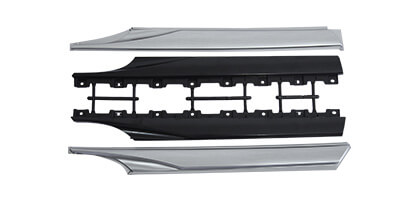

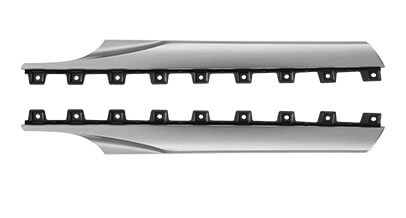

INS Injection Molding Process

The full name of INS is Insert-Mould-Decoration (embedded membrane type injection molding decoration), a special type of plastic injection molding, put the thermoforming-film into the mould for further injection molding to a complete part.

The INS process is a new process derived from IML process. Because of the increasingly high requirements for ecological environment protection in various countries, INS technology has been widely used in modern advanced manufacturing industries, such as automobile interior decoration, household appliances decoration, intelligent digital shell, and gradually replaced the spraying, electroplating and other surface treatment processes with environmental pollution.

The plastic parts made by INS process have abundant surface expressiveness. They can be bright, matt, metal, wood, leather,2D plane and 3D. There are thousands of types of INS film at present. For new product ID surface selection, there is a big space to choose the method of appearance expression. Because the surface of INS process can achieve metal texture, but does not shield signals, and because the requirement of 5G for signals is much greater than that of 4G, INS has become an indispensable technology for the new generation of intelligent hardware in order to make 5G intelligent digital have metal texture and good signal transmission function.

Industrial design

Industrial design

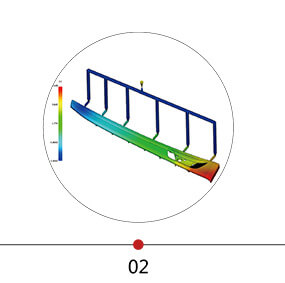

Feasibility analysis of INS moulding of plastic parts

Feasibility analysis of INS moulding of plastic parts

Mould design

Mould design

(film forming mould, film punching cutting dies, injection mould)

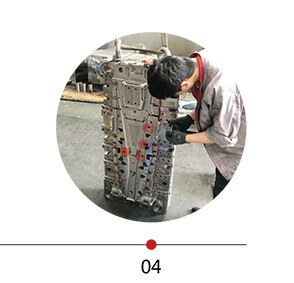

Mould making

Mould making

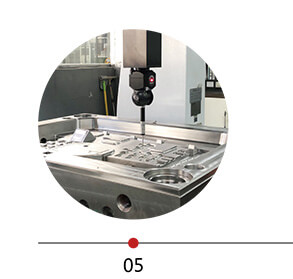

Mould testing

Mould testing

Mould qualified

Mould qualified

Small batch trial production

Small batch trial production

Batch supply

Batch supply

Continuous Innovation

Striving for progress and continuous innovation to make the best plastic mould, lead the plastic molding industry in INS technology.

Excellent Service

Strong supporting service system, there are experienced production partners in blister, die cutting and injection molding.

Perfect INS Projects

Offer the perfect INS projects for domestic famous auto parts manufacturers.