Medical injection molding (also called clean injection molding) is an efficient way to produce durable medical equipment. In this article, we are going to introduce some important details about medical injection molding. Medical injection molding is a process in which molten plastic is injected into a mold of medical products and cooled to obtain desired medical equipment. Medical injection molding has a wide usage ranging from disposable syringe and test tube to breathing machine and CT machine. More and more medical equipment are made of plastic through medical injection molding. For people working in the medical industry, medical injection molding products have advantages of being durable and not easy to wear that it can reduce the consumption of medical equipment and then reduce cost. And for people working in plastic injection molding industry, medical injection molding is a cost-effective way to produce disposable plastic medical equipment with excellent accuracy and consistency. Medical equipment is usually used in laboratory, hospital and other medical facility.

o. Obligation for medicalequipment to be clean

With a strict requirement for accuracy and cleanness, medical equipment made through medical injection molding need to pass plenty of strict health regulations and industry standards, such as FDA standards (abbreviation of U.S. Food and Drug Administration), before being put into the market. In order to pass those standards for cleanness, medical injection molding should be processing in a dust-free workshop by medical special clean injection molding machine. On the meanwhile, in order to keep accuracy, medical injection molds should be precisely tooled to keep final products precise and transparent. Since most medical equipment made through medical injection molding are disposable, it’s of vital importance to improve productivity. Multi-cavity design for medical injection mold make it possible to make multiple products in one cycle. With growing concern about health and continuous development of the medical industry, whether medical injection molding machine, medical injection mold or medical injection products, there are broad market prospects and growth space.

The use of plastics in modern medicine has steadily increased. Medical equipment made from injection molding help reduce medical costs, infectious diseases and pain management. Medical injection molding directly enhances patient safety and the ability to save more lives.

1. Efficient and Cost-effective

Mass production and mass delivery help reduce unnecessary costs and maximize efficiency in medical injection molding. When producing a large amount of medical equipment, medical injection molding process can reduce the cost of each component.

2. High Cleanness

Only medical equipment approved by the FDA can be used commercially. Medical injection molding is a way to produce durable and reliable medical-grade plastic components that meet FDA standards.

3. High Precision

Medical equipment requires high precision and accuracy. Strict tolerance range in medical injection molding ensure precision and accuracy of plasic medical equipment.

4. High Safety

Most plastic medical equipment made by medical injection molding are disposable. Their use-and-throw characteristics help reduce the risk of cross infection to protect patients' safety.

Plastics have become important materials for medical equipment due to their unique properties, such as strong corrosion resistance, durability, water resistance, light weight, flexibility, and low cost.

Biological and mechanical properties will not affected through sterilization process.

Good tooling performance and easy to process into various shapes of products with low cost.

Medical grade material with less heavy metal content, low content of soluble matter and soluble matter.

Good anticoagulant property when the material is in contact with blood and does not cause protein degenerati and destroy the tangible components.

Polypropylene (PP)

Acrylonitrile Butadiene Styrene (ABS)

Polyethylene (PE)

Polystyrene (PS)

Polycarbonate (PC)

Others

In medical injection molding, all equipment should be qualified and verified GMP standards (abbreviation of Good Manufacturing Practice) to ensure products' high cleaness, precision and accuracy.

Equipment Sino Owned for Medical Injection Molding:

| Category | Equipment Name | Quantity | |||||

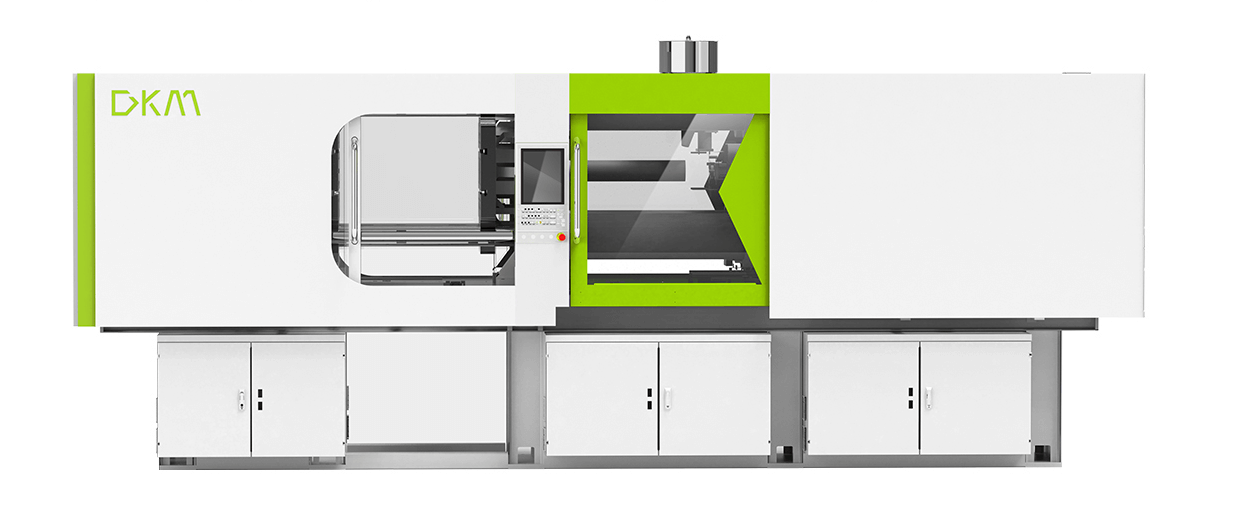

| Medical Special Injection Molding Machine | DKM Clean Injection Molding Machine-MX Series | 20 | |||||

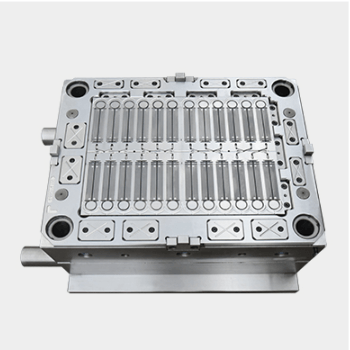

| Medical Injection Mold | Syringe Mould | 8 | |||||

| Pipette Tips Mould | 5 | ||||||

| Test Tube Mould | 6 | ||||||

| Petri Dish Mould | 4 | ||||||

| Oxygen Mask Mould | 3 | ||||||

| Protective Eyewear Mould | 2 | ||||||

| Infusion Set Mould | 2 | ||||||

| Dust-free Workshop | 3 | ||||||

| Auxiliary Equipment | Syringe Pad Printing Machine | 10 | |||||

| Syringe Assembly Machine | |||||||

| Syringe Blister Packing Machine | |||||||

Plastic medical equipment made by injection molding such as syringes and pipette tips have a high requirement of production cleaness. However, problems such as oil pollution, particle volatilization and air disturbance are easy to occur in plastic processing, leading to the damage of product cleanliness. Traditional hydraulic injection molding machine is easy to cause oil pollution in the injection molding process comparing to electric injection molding machine. Therefore, most medical injection molding manufacturers prefer to choose electric injection molding machine and more and more plastic injection molding machine brands have entered this race.

DKM Machinery, the brother of SINO MOULD, has developed medical special injection molding machines - EH Series. DKM medical injection molding machine with full electric injection unit and servo motor system realize the high speed and precision injection. EH series injection unit without hydraulic system and using special self-lubrication design for clamping device hinge lubrication to ensure no pollution in workshop.

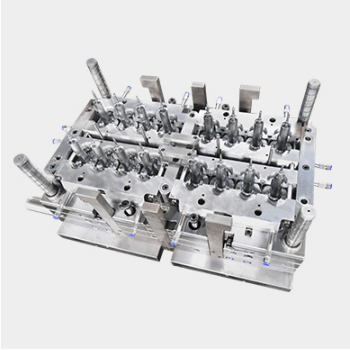

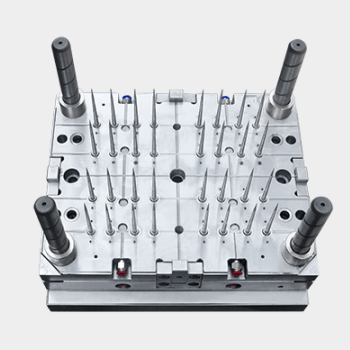

Mold should choose anti-rust and anti-corrosion materials, such as S316 stainless steel.

Mold design should fully consider the location of sprue and the arrangement of some core and ejector pin that easy to cause stress.

Since medical equipment have very strict requirements for size and post-deformation, the design of mold cooling line should fully consider the uniformity of products cooling to prevent post-deformation caused by uneven cooling.

The strict requirement of cleanliness for medical equipment requires a hygienic production environment. Dust-free workshop is essential for medical injection molding. SINO owns different levels of dust-free workshops with multiple sets of plastic injection molding machines in different tonnages to undertake medical injection molding OEM.

Syringe Pad Printing Machine

Syringe Assembly Machine

Syringe Blister Packing Machine

Injection molding used for plastic medical equipment like syringes, test tubes, petri dishes, pipette tips, oxygen masks, etc.

Thin wall molding, gas-assisted injection molding, 3D printing, metal injection molding and liquid silicone injection molding.

Develop a complete set of plastic mold production management system to organize the information of mold design, mold processing and products mass production.

Medical injection molding is a breakthrough for medical industry that provide a more inexpensive and more efficient way for medial equipment manufacturing.