Paint bucket molds face multiple technical challenges during manufacturing, including thin-walled high precision, the conflict between high-speed production and cooling, and compatibility with IML. This Blog systematically analyses these difficulties and their innovative solutions, assisting industry clients in achieving efficient, high-quality, and stable paint bucket production.

Problem:

Non-uniform wall thickness causes eccentricity and sink marks; 20L thin-wall paint bucket (weight <650g) are prone to deformation.

Solutions:

Utilize high-precision machining equipment (accuracy ±0.01mm) to ensure mold dimensions.

Mold Steel: P20/718H base + Beryllium copper inserts (rim/bottom).

Cooling Bar Technology (Industry Pioneer): Only 6mm from cavity surface, reducing production cycle by 30%.

Problem:Cooling time accounts for 80% of the cycle; traditional mould cycle >30 seconds.

Innovative Solutions:

Sandwich Cooling System:

Bottom insert: Beryllium copper material for accelerated heat dissipation.

Rib positions at the rim: Independent circulating water channel groups.

Slant ribs on sliders: Insert structure + circulating water channels.

Result:20L paint bucket production cycle compressed to 14.8 seconds (standard wall thickness).

Challenge:The label position interferes with the gate, resulting in a weld line.

Key Technologies:

Gating System: Valve-gated hot runner system (ANOLE System).

No gate vestige, reduces cavity pressure.

Adapts to full-wrap labelling for round and square paint buckets.

Robot: European standard 12/67 signal port direct connection, supports top or side feed selection.

Selection of mold steel.

Product structure is suitable for IML.

Multi-cavity molds require consideration of arrangement (Centre distance and orientation).

The positioning of the film affects the design of the adhesive application points.

Height:Engine oil buckets: 1.5-3 meters (Standard buckets: 1.2 meters).

Angles:45°/90° angles + Suspension drop.

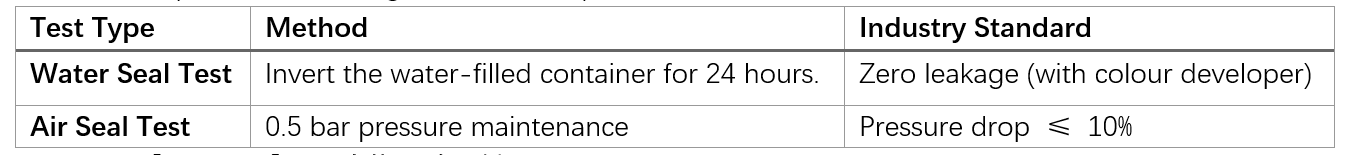

Pass Criteria:

Bucket body no rupture (minor scratches allowed).

Lid zero displacement.

No leakage after tumbling.

Stacking Test:Stack 3 layers filled with liquid (≥72 hours).

Compression Test:Press down with a compression tester until 10% deformation.

Key Data:20L bucket load-bearing capacity ≥ 200kg.

To successfully make paint bucket molds, it is important to control key technologies. These include thin-wall precision, cooling efficiency and IML compatibility. It is also important to do rigorous sealing and strength testing. Clients should choose suppliers offering high-precision machining, innovative cooling systems and mature IML solutions. This will ensure products maintain exceptional quality and stability during high-speed production.