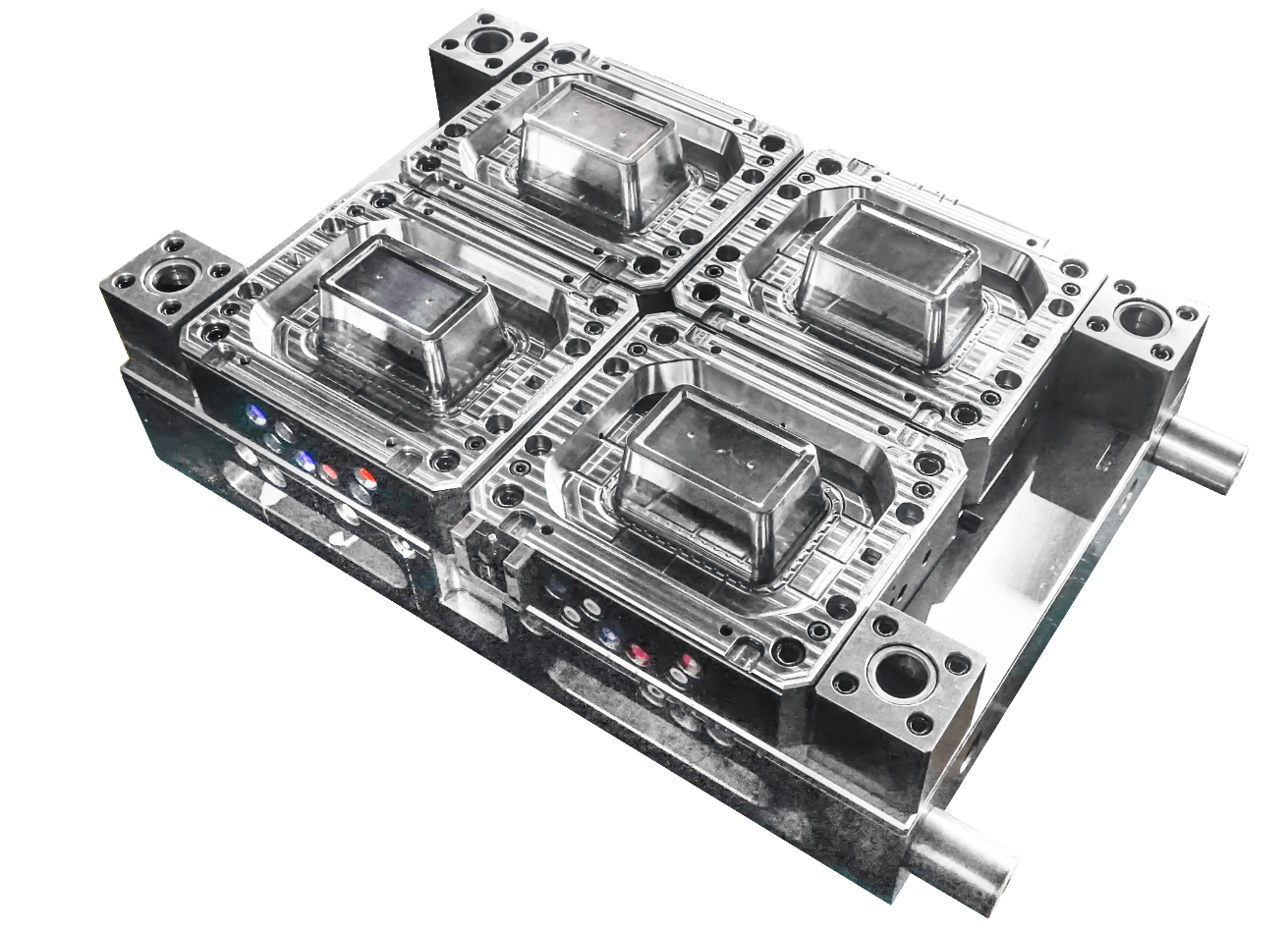

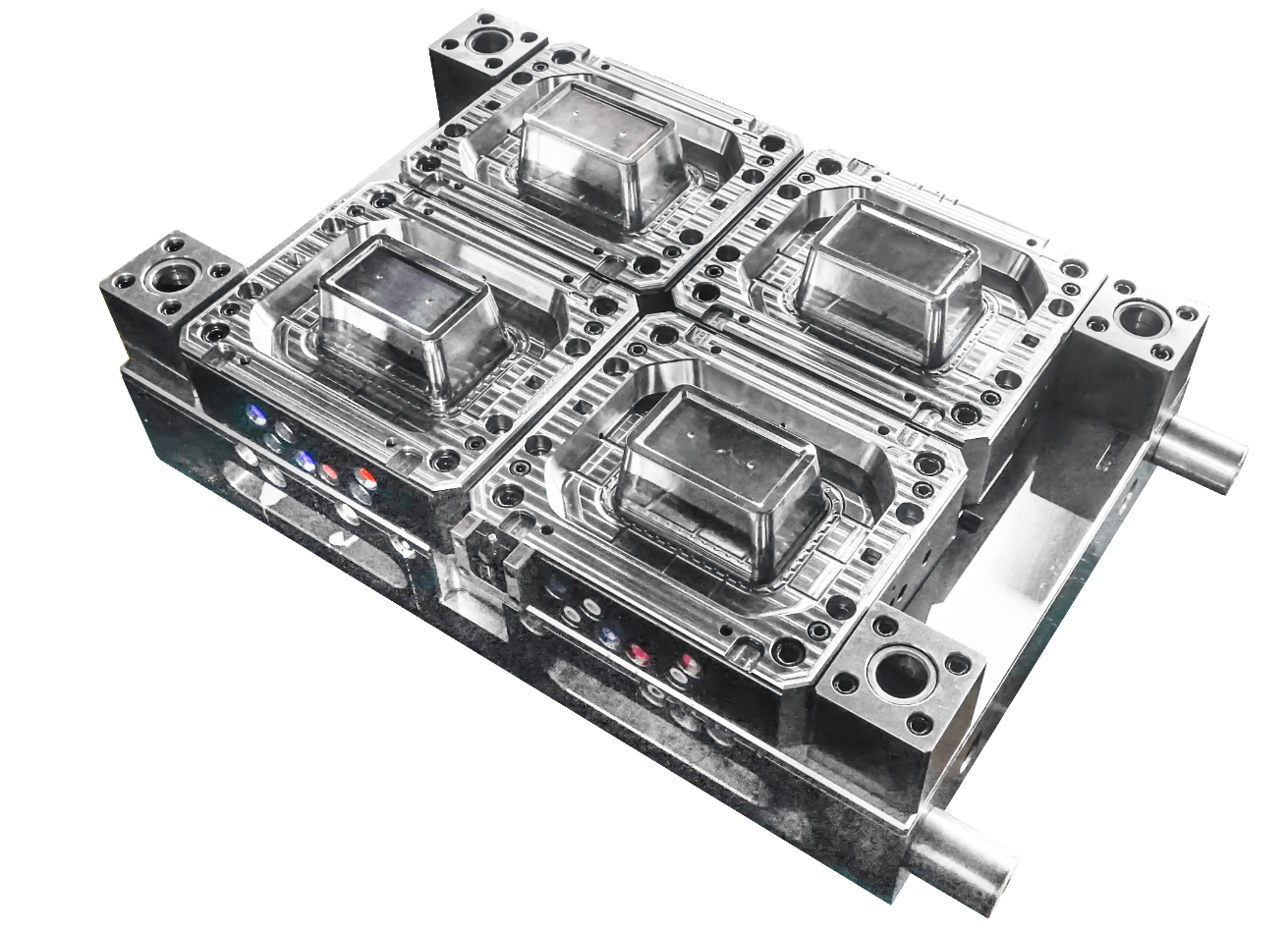

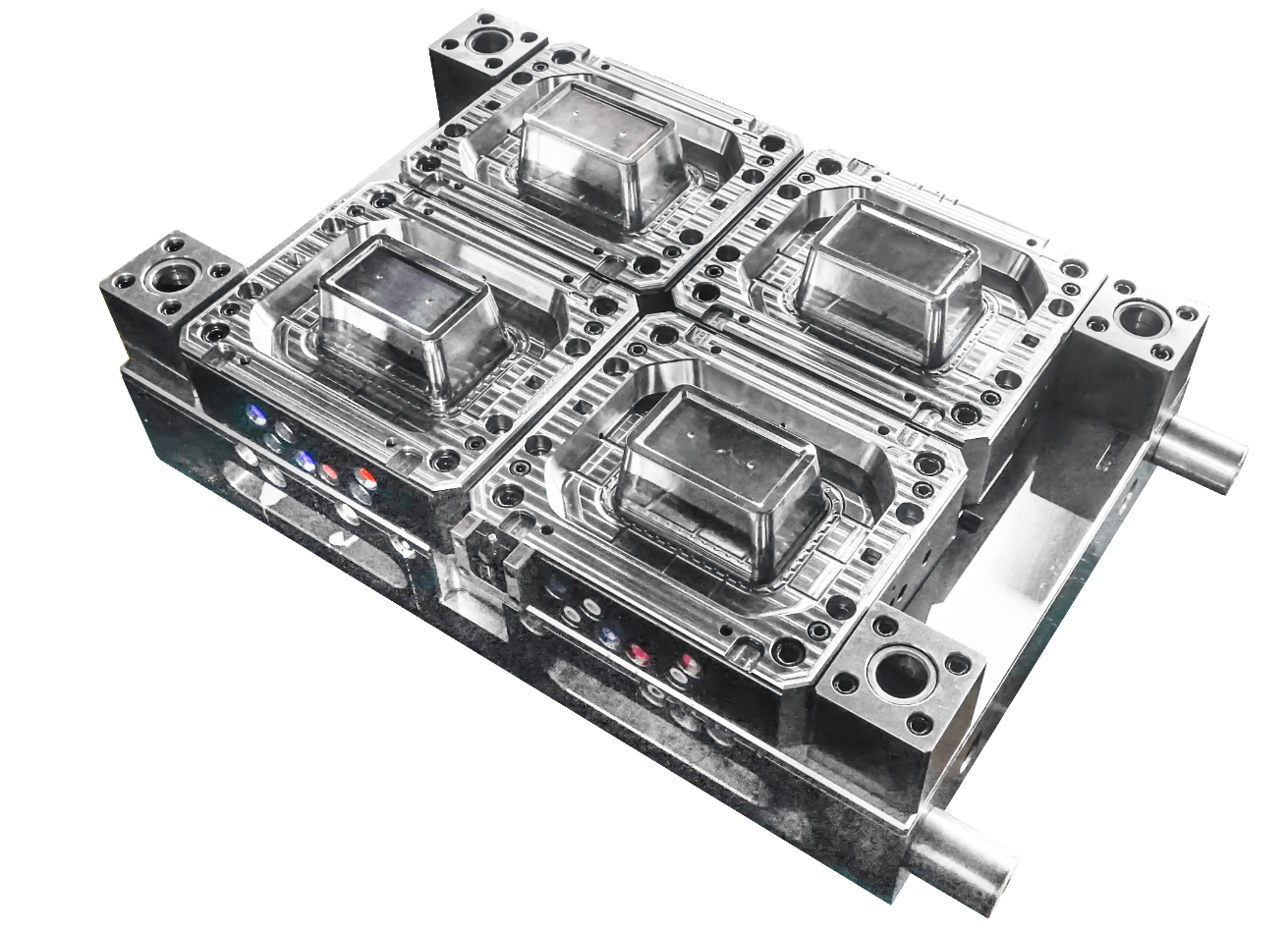

Sino Mould manufacture more then 600 sets of Thin Wall moulds annually and is the expert in disposable Thin Wall Container moulds. Sino Mould has 15 years of experience in research and manufacturing of disposable Thin Wall Container moulds.

From 50ml to 5000ml, from round to square disposable Thin Wall containers mould, it can reach 1-32 cavities arrangement. Under normal condition, we recommend our users choose the following number of cavities: 1, 2, 4, 6, 8, 12, 16, 24, 32. Of course, the arrangement of cavities also needs to be accurately selected based on the user's production capacity and machine size.

The selection of steel for disposable Thin Wall Container moulds is very important. Due to the high-strength compression and heating of the core cavity, we usually use tempered steel materials for thin wall mould. For example, S136, DIN1.2316, DIN2083, DIN1.2344, or DIN1.2343. General mould suppliers may use ineffective steel materials such as S136, but for professional users who understand the basic maintenance of moulds, SINOMOULD recommends using DIN1.2344 or DIN1.2343.

SINOMOULD's disposable Thin Wall Container Moulds adopts an intelligent machining production line. After half precision CNC milling of the core and cavity, the qualified core and cavity inserts blocks will be automatic well done on the intelligent machining production line.

All tooling steps will be automatic processed by this production line for fully automatic fixing, cleaning, drying, and critical dimension inspection. The dimension tolerance can be ±0.005mm.

SINOMOULD's disposable Thin Wall mold hot runner system generally adopts valve gate hot nozzle type, which is a hot runner system developed by the brand ANOLE under SINOMOULD, with more than 15 years of hot runner technical experience. The application on Thin Wall molds has exceeded 3000 sets.

The air venting system of a disposable Thin Wall Container Moulds is very important, and the depth of the air venting groove is generally 0.015mm. However, through what processing can this picky size be achieved? What measurements can be used to verify the accuracy of this dimensions? This is a problem that normal mould companies cannot solve.

If the air venting system of a disposable Thin Wall Container Moulds is not made accurately enough, either the plastic part will have flashes, or the injection molding is unstable, and the mold cavities cannot be perfectly filled.

After the SINOMOULD disposable Thin Wall Container Moulds is ready, we need to conduct high-speed mass production simulation testing, which usually requires high-speed automated operation for more than 4 hours. We need to ensure that the range of the injection molding parameter adjustment is large, in order to ensure the convenience of user adjustment and production stability.

The delivery time for SINOMOULD disposable Thin Wall Container moulds is 35-45 days. We strive to deliver within 30 days, and we believe we will soon achieve this goal.

SINOMOULD established the <Technical Standards for Disposable Thin Wall Container Molds> and <Material Inventory Standards for Disposable Thin Wall Container Molds> in 10 years ago, and we have spare parts prepared with the mould shipment, making it very convenient for users to replace them. Even if the parts are shipped from China, it is very fast because we have ready-made parts in our warehouse.