Our company manufactures many kinds of the China plastic injection crates molds, such as: vegetable crates molds, coca-cola crates molds, bread crate molds, chicken crate molds, milk crate molds, fruit crate molds, etc. We are China plastic injection crates molds supplier for about 20 years with rich plastic injection mold experience.

We can use P20, 718, 2311, 2344, etc steel material to manufacture the plastic injection crate molds in our factory, if the customers have their own ideas of the mold steel, we will adopt customers?ideas and offer our professional solution for our customers, with the senior engineers and the designers mold experience, which will offer our customers a best solution of the mold design and the mould steel. Our company ever made one to four cavities crates mold, with get our customers good feedback.

Besides, in order to let our customers feel we are more professional and make customers feel more convenient, our company also good at plastic injection molding machines and the after sales service. We firmly believe that we will offer you a good mold and a good solution, You can also visit our website: http://www.dakumar.com

If you are also interested in our plastic injection crates molds and the injection molding machines, please contact me. We are China plastic injection crates molds.

Posted by Candy

export@sinomould.com

whatsapp: +86-15858685263

Our company is specialized in making plastic injection molds turnkey service that means we can offer our customers a completely matched products, such as : juicer extractor molds, building block molds, baby slid mould, whole sets of the baby toys molds, etc. Our company can provide our customers high quality the turnkey service of the plastic injection molds and good after after sales service.

We are plastic injection molds turnkey service manufacturer in Taizhou, China. when you place the order, our product design department will make a totally measurement test of the samples and make the product design of the matched design. After our first trial, we are going to match it and make the measurement of the test of all the samples, then our quality inspector and our engineers will make the measurement report to our customers, once our customers confirm the samples, the molds will be ship soon. you can also visit our plastic injection molds website: http://www.sinomould.com

We are offering the plastic injection molds turnkey service and also matched plastic injection molding machines and the relative auxiliary machines. Once you need help or have other questions, pls feel free to contact me, we will send you the related information to you. you can also visit our website: http://www.dakumar.com

Posted by Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

editor: Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

What is big part product?

Why you need to find the professional big part injection moulds supplier?

what is the advantage of Sino?

editor:Celina

Skype: sinomould.dakumar7

Email: export@sinomould.com

Sino Mould is a full service offer located in China, offering high quality prototyping service, plastic mould customized and plastic injection molding service. As a main plastic injection molding company in China, Sino has rich experience and strong capability in offering molding service.

Regarding to our experience in offering plastic injection molding service, Sino has offered molding service for various products. We can offer plastic molding service for home appliance mould, for automotive part mould, for component mould, for PVC pipe fitting mould, for PET preform mould, for industrial component, etc. We can accept customized package of product.

Regarding to our capability, we have injection machine ranging from 50T to 1800T. So we can handle with almost main plastic product in the market.

Regarding to our price, we are always offering best price for plastic injection molding service because we offer you both moulds and molding product. If your productivity is big enough, we can even return part or all of your mold cost!!!

Besides mould and plastic molding service, we can offer you also prototyping service. You can have a sample before making moulds with prototyping to check the product design. If it is OK, then you make moulds. If not OK, then you modify the design. This can save you a lot of cost at the first stage.

Sino will be best partner for plastic mould and plastic injection molding service by offering you full-service to help you develop new product. If you have any interest, please contact me.

Gas-assisted products are very common, such as gas assisted chair, gas assisted automotive parts and so on. Thus, the gas-assisted injection molding process is crucial to products.

As for gas needle type panel mould, when press the air into gas needle, it is easier to produce inlet imbalance which will increase difficulties to debugging. The main phenomenon is shrinkage. In this case, we always check the gas fluency when deflate.

The temperature of the plastic is one of the main factors which will influence the normal production. The quality of the gas assisted products is very sensitive to the plastic temperature. If the temperature of the plastic in the nozzle is high, it will cause the phenomenon of burning and silver streaks. On the contrary, if the temperature of the plastic in the nozzle is low, it may generate cold glue, cold nozzle, seal gas needle and other phenomena. And the products always appear shrinkage and silver streaks. What we can do is to check whether the temperature of the plastic is reasonable.

Check whether the gas assist induction switch is sensitive or not. Otherwise, it will cause a lot of unnecessary losses.

The pressure maintaining of gas assisted products depends on the gas. When the shrinkage of products happens, we can reduce the plastic to prevent this trend. This measure is always adopted to reduce the pressure and apace of the inner of the products, and then the gas will be easier to penetrate the thick plastic place to fill pressure.

Welcome to Chinese professional mould manufacturer——Sino Mould. We have much experience in this field. If you are interested in our moulds or any other product, please don’t hesitate to contact me for molds and plastic molding service.

A chair mould will be influential to produce final chairs. But how to manufacture chairmoulds? It may become a big problem. During the process of manufacturing chair mould, many factors should be taken into account.

Manual operation in the parting line will be easier to cause asymmetrical wall thickness. Of course, most of the reasons are due to the bad 3D design and bad polish of the cavities and cores. Thus, when we begin to design a chair mould, we should take the wall thickness into account. Sometimes, we will have to make much thicker in some areas in order to assure the strength of the chair. But we also should be more carefully if we adopt this method. As we know, asymmetrical wall thickness will lead to the asymmetrical injection, cooling asymmetrical, accordingly. And then it will slower the speed of injection and result in epitome simultaneously. If the process of CNC milling is not very accurate, you cannot get a chair with symmetrical wall thickness.

How to assure the chair has enough strength but light?

We should consider the weight and strength of the chair when we design the chair. You can make the bottom of the chair much stouter by increasing more reinforcing ribs. How about the chair feet, back of chair and cushion. As for this, you should analyze force of every area. In order to make the light chair with good strength, PP will be best choice.

How to design good venting system on the back of the chair?

The back of some chairs are more complicated because they have many plastic weld. It may cause bad venting when filling the material and plastic flow. We need to use moldflow analysis to estimate whether the certain areas of mould need venting system or not.

How to assure the durability of the chair mould?

We should assure the steel material has been plated chromium in order to prevent the cavities and cores from being corroded by plastic. Provided that you want to use return material, the chair mould must be chromium plated. Otherwise, the mould needs to be polished frequently.

Welcome to Chinese professional plastic injection mould manufacturer——Sino Mould. We have a full-equipped factory in Southeast of China, Huangyan. We have much experience in this field. If you are interested in our products, please don’t hesitate to contact us for molds and any other plastic molding service.

Light weight pallet

Need to order low weight pallet molding for size from single face pallet supplier,European pallet moulds maker,pallet crate supplier China,recycle pallet Chinese supplier,plastic tray molds supplier in China, you can come to SINO MOULD. Offering the turnkey solution for low weight pallet molding service as well as high quality mould.

With low weigth pallet, which also named light weight pallet, you can save the transport cost for your business, but it suitable for low weight product, and still durable, easy handling and sturdy for your daily work. For example, we make low weight pallet with weight from 1200x800mm of 12kg, the overall height is 145mm. which can carry even up to 2500LBS or more.

The design have still various, such as two face, single face and more different size and Nestable in small space. You can come to enquiry and will offer you our best price.

If you are interested, please contact export@sinomould.com

Or send your enquiry to Skype: sinomould.dakumar2![]()

Injection chair mould manufacturerand injection chair molds supplier Sino Mould is a world famous plastic chair China mold company.

Sino Mould offer various kind of injection chair mould, such like fold chair, gas-assisted chair, dinner chair, art chair, children chair, bus chair, etc. We have a high efficient team with 4 design department, production department, quality control department and after sales service department. We have own Quality Control department to do the inspection for mould cooling water system, hydraulic cylinder and other standard mould inspections. It will be more than 20 staffs working for your project. Our subcompany Dakumar Machinery Co.,Ltd supplies you high performance injection moulding machine, and Anole Plastic Moulding technology Co.,Ltd offers high quality Hot Runner system.

Sino Mould offers high quality injection chair mouldswith reasonable price. If you have some injection chair mould projects, please contact me for detail information. As we say “seeing is believing”. Welcome to your enquiry and down visit.

Miss Summer

Skype: sino-mould02

MSN:export@sinomould.com

Mail: export@sinomould.com, export@sinomould.com

Web: http://www.cnmould.com

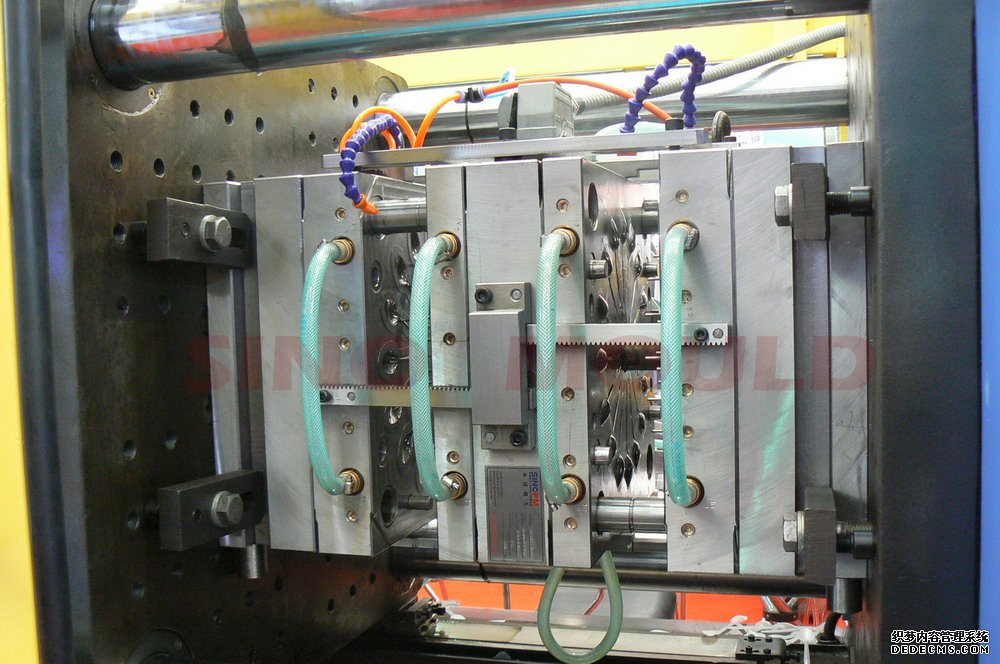

Sino mould is the big mould factory, who have many years’ experience in making the mould in the various fields. like daily use commodity mould, including the stationery mould ,ball pen cover mould is one of the hot products we made. We are the famous Chinese ball pen cover mould manufacturer.

Mould cavity/core steel: DIN 1.2344, p20

Mould cavity: single/ multi cavities

Mould gate: sub-marine gate

Suitable injection machine: DKM 118T DKM-268T

plastic material: PP PVC PU ABS……

If you interested in making the ball pen cover mould ,pls feel free to contact me.

The plastic fork,platic spoon, plastic knife is the popular in the market, considering the massive production of fork, spoon or knife, and products’ low area and thin height, is very suitable for make stacking mould, it will be enhance efficiency of the injection machines and saving production cost.